Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Coal, cement, ore, calcite, cement clinker, dolomite, clay, barite, etc. in cement industry, building materials, thermal power, metallurgical industry, chemical industry, etc.

Coal mill is a kind of ball mill, which is often used to crush and grind coal bricks into powder. As the main equipment in the cement plant, it can be used for the milling of coal. Therefore, it is also called coal grinding mill. For its functions, coal mill has wide applications such as coal mill in power plant, in the metallurgical and chemical industry, or in the building materials industry. It is suitable for making coal and mineral material powder. Coal mill has reasonable structure and high grinding efficiency, which is the ideal equipment for coal preparation.

Coal Mill

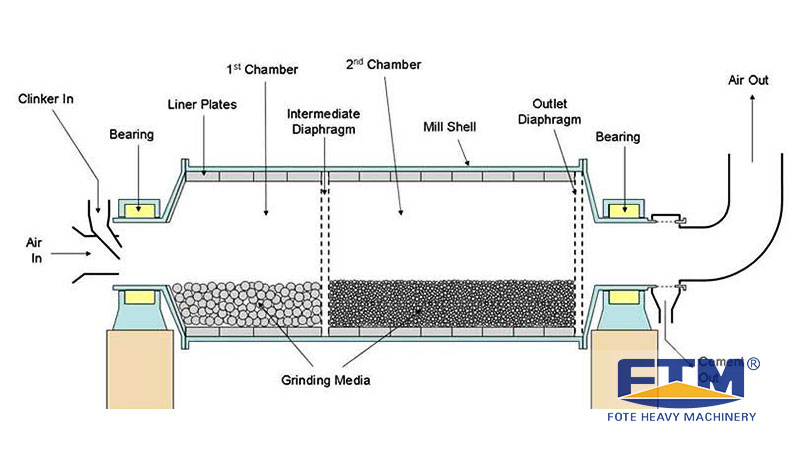

Coal mill is mainly composed of feeding device, main bearing, rotating part, pulverized coal burner, discharging device, high-pressure starting device and lubrication system.

When coal mill works, raw material enters into the mill by feeding device, then hot air at about 300℃ blows into the cylinder through the inlet pipe. In the drying bin, special lifting plates are arranged to lift up the raw coal, so that the raw coal can be dried by strong heat exchange here. Then the dried coal enters the grinding bin through the double-layer partition plate with the lifting plate. Grinding body (steel ball) is installed in the grinding bin, in which the coal is crushed and ground into pulverized coal. While the coal is crushed, the pulverized coal and gas are brought out of the mill by the special induced draft fan through the air cleaning coal grinding device. The thicker particles will be returned to the grinding bin through the return screw of the discharge device for re-grinding.

Working Principle of Coal Mill

Coal mill has a combination design of grinding liner and drying bin, which adopts different lining board structure according to different stages of the coal mill, which makes the coal mill reach a productivity of 3~40TPH. This is a process of great high-efficiency and energy-saving as well as cost savings.

The feeding device adopts the louver structure with oblique inlet air that enhances the heat exchange capacity of the mill, which can effectively prevent the material blockage phenomenon at the entrance of the coal mill; an optimized supporting system improves the lubrication structure and reduces the resistance of the system.

According to different requirements from various scaled plants, coal mill can adopt edge transmission or center transmission equipped with an advanced control system, which has a flexible configuration.

>>Scene One

Customer: There is a leakage in the main bearing part of my coal mill. What shall I do?

FTM Engineer: It may be caused by the loose joint of the water pipe and the cracks in the spherical tile. You can reassemble the joint with sealant, repair the crack by bonding method or repair welding method, or replace the tile.

>>Scene Two

Customer: What can I do to deal with the material leakage at the feeding end?

FTM Engineer: It may be due to the large gap between the feeding slip and the feeding spiral cylinder and between the feeder and the funnel, resulting in the poor sealing; or it may due to the wears or falling-off of the felt pad. You can adjust the clearance and seal it, or replace the pad.

In India, the FTM coal mill used in a cement plant is with the production capacity of 30TPH.

Fote Machinery has coal mill for sale, which has stable performance, advanced technology, simple structure and complete models. Last but not least, the coal mill price of our company is the most reasonable among coal mill manufacturers. Professional Fote engineers are here ready to offer you a free consultation!

| Spec. (m)Item | Φ1.7×2.5 | Φ2.2×4.4 | Φ2.4×4.75 | Φ2.4×4.5+2 | Φ2.6×5.25+2.25 | Φ2.8×5+3 | Φ3.0×6.5+2.5 | Φ3.2×6.75+2 | Φ3.4×6+3 | Φ3.8×7+2.5 | |

| Speed(r/min) | 24.5 | 22.4 | 20.4 | 20.4 | 19.7 | 18.3 | 18.3 | 16.9 | 17.5 | 16.4 | |

| Capacity(t/h) | 3-5 | 8-9 | 12-14 | 11-12 | 13-14 | 16-17 | 19-20 | 25-30 | 28-30 | 38-40 | |

| Feeding Size(mm) | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | |

| Grinding Media Loading(t) | 7.5 | 20 | 22 | 22.5 | 28 | 32 | 43 | 50 | 55 | 80 | |

| Main Reducer | ZD40 | ZD60 | ZD60 | ZD60 | ZD70 MBY450 |

ZD70 MBY500 |

ZD80 MBY560 |

JDX560 | JDX710 | MBY800 | |

| Main Motor(kw) | 95 | 250 | 280 | 315 | 400 | 500 | 630 | 710 | 800 | 1250 | |

| Weight(t) | 29 | 46 | 54 | 76 | 98 | 107 | 124 | 148 | 162 | 215 | |

| Spec.(m) Item | Capacity (t/h) |

Feeding Size (mm) |

| Φ1.7×2.5 | 3-5 | <25 |

| Φ2.2×4.4 | 8-9 | <25 |

| Φ2.4×4.75 | 12-14 | <25 |

| Φ2.4×4.5+2 | 11-12 | <25 |

| Φ2.6×5.25+2.25 | 13-14 | <25 |

| Φ2.8×5+3 | 16-17 | <25 |

| Φ3.0×6.5+2.5 | 19-20 | <25 |

| Φ3.2×6.75+2 | 27-29 | <25 |

| Φ3.4×6+3 | 28-30 | <25 |

| Φ3.8×7+2.5 | 38-40 | <25 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat