Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Non-ferrous metal ore such as gold, copper, lead, zinc, etc., black metal ore like manganese, chrome, non-metallic ore like talc, feldspar, zeolite, etc.

Over 200 Exported Countries: South Africa, Kenya, Mexico, Indonesia, France, Congo, America, Ailbaria, Malawi, Pakistan, Iran, etc.

Flotation machine, also called flotation cell, is the equipment to complete the flotation process. It is widely used for the rough, fine and reverse flotation operations of copper ore, lead ore, zinc ore, nickel, molybdenum and other non-ferrous metal, ferrous metal and nonmetal minerals. The types of flotation machine mainly include mechanical agitation flotation machine and froth agitation flotation machine.

Flotation machine can be used for separating copper ore, lead-zinc ore, molybdenum ore, graphite ore, fluorite ore, phosphate, selected gold, silver, iron, rare earth ore, talc and so on. It is widely used in the separation and recovery for fine minerals of ferrous metal, precious metal, nonferrous metal, non-metallic minerals, rare metal, non-metal, etc.

Applications of Flotation Machine

The flotation cell has high separation efficiency, which greatly expands the scope of mineral resources and increases the recycling rates. It has relatively stable and large inspiratory capacity with good circulation performance, low power consumption, low pharmaceutical consumption, simple structure and convenient adjustment.

It is equipped with advanced control system, which can realize automation control. The groove has the suction of air and slurry as well as the flotation loop. Without using foam pump, the horizontal configuration is easy for process changes.

Flotation machine is widely used as the copper separation equipment, gold separation equipment, limonite ore dressing equipment, lead-zinc ore washing equipment, etc.

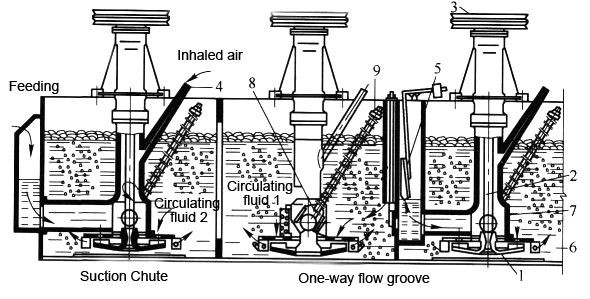

The Structure of Flotation Machine

The flotation machine is driven by the motor triangular belt to drive the impeller to rotate, and the centrifugal force is generated to form a negative pressure. On the one hand, the sufficient air is inhaled and mixed with pulp, on the other hand, pulp and medicine are mixed, and foam is refined so that minerals can stick to foam and float to the surface of pulp to form mineralization foam. Adjust the gate height to control the liquid level so that the useful foam is scraped out by the scraping plate.

The Working Principle of Flotation Machine

The flotation machine is mainly composed of slurry tank, agitator, aeration device, discharge mineralization bubble device and electric motor. The impeller has low peripheral speed and a long life of the impeller cover. The slurry is subjected to the upper and lower double cycles in a fixed manner, which is beneficial to the suspension of coarse minerals.

Flotation machine adapts mechanical agitation, simple operation, convenient adjustment, and long service life of wearing parts. Without any auxiliary equipment, the flotation machine is highly configured by itself, and it has functions of suction and flotation.

Before starting the machine, check the bolts in all parts; before stopping the machine, manually replace the wheel rotation to prevent sediment deposition and increase the load of the motor. The height of the gate should be carefully adjusted to keep the liquid level stable, and the mineralized foam on the slurry level should be scraped into the flow groove at any time. The impeller and stator should be kept at a certain distance. When it worn, you should be taken to replace them. The bearings in the pump should be serviced once every three months.

Flotation machine consumables: impeller, stator

Fote Machinery has various types of flotation machine for sale, in addition to froth flotation machine, we also have copper ore flotation machine. The flotation machine produced by FTM company has advanced structure, reliable performance and favorable price. If you want to know more details about flotation machine, please contact us!

| Category | Specification Model | Effective cubage (m³) | Processing capacity (m³/min) | Main shaft loam board | Dimensions (L×W×H) (m) | Single trough Weight (t) | |||

| Power (kw) | Rotate speed (r/min) | Rotate speed (r/min) | Power (kw) | ||||||

| XJK type flotation machine | XJK-0.35 | 0.35 | 0.18-0.4 | 1.5 | 483 | 25 | 1.1 | 0.7×0.7×0.7 | 0.5 |

| XJK-0.62 | 0.62 | 0.3-0.9 | 3.0 | 400 | 25 | 1.1 | 0.90×0.82×0.85 | 1.0 | |

| XJK-1.1 | 1.1 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1×1.1×1 | 1.4 | |

| XJK-2.8 | 2.8 | 1.5-3.5 | 11 | 280 | 25 | 1.1 | 1.75×1.6×1.1 | 2.5 | |

| XJK-5.8 | 5.8 | 5-7 | 22 | 240 | 25 | 1.5 | 2.2×2.2×1.2 | 3.6 | |

| SF type flotation machine | SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 386 | 25 | 1.1 | 0.7×0.7×0.75 | 0.5 |

| SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 0.9×0.82×0.95 | 1.0 | |

| SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1×1.1×1.1 | 1.9 | |

| SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1.75×1.6×1.15 | 2.6 | |

| SF-4 | 4 | 2-4 | 15 | 220 | 25 | 1.5 | 1.85×2.05×1.2 | 2.9 | |

| SF-8 | 8 | 4-8 | 30 | 191 | 25 | 1.5 | 2.2×2.9×1.4 | 4.2 | |

| SF-10 | 10 | 5-10 | 30 | 191 | 25 | 1.5 | 2.2×2.9×1.7 | 4.5 | |

| SF-20 | 20 | 5-20 | 30×2 | 191 | 25 | 1.5 | 2.85×3.8×2 | 9.9 | |

| JJF type flotation machine | JJF-2 | 2 | 1-3 | 7.5 | 443 | 25 | 1.5 | 1.4×1.4×1.1 | 1.7 |

| JJF-4 | 4 | 2-4 | 11 | 305 | 25 | 1.5 | 1.6×2.15×1.25 | 2.4 | |

| JJF-8 | 8 | 4-8 | 22 | 233 | 25 | 1.5 | 2.2×2.9×1.4 | 4.5 | |

| JJF-10 | 10 | 5-10 | 22 | 233 | 25 | 1.5 | 2.2×2.9×1.7 | 4.9 | |

| JJF-16 | 16 | 5-16 | 30 | 180 | 25 | 1.5 | 2.85×3.8×1.7 | 8.0 | |

| JJF-20 | 20 | 5-20 | 37 | 180 | 25 | 1.5 | 2.9×3.8×2.0 | 10.5 | |

| Category | Specification Model | Effective cubage (m³) | Processing capacity (m³/min) |

| XJK type flotation machine | XJK-0.35 | 0.35 | 0.18-0.4 |

| XJK-0.62 | 0.62 | 0.3-0.9 | |

| XJK-1.1 | 1.1 | 0.6-1.6 | |

| XJK-2.8 | 2.8 | 1.5-3.5 | |

| XJK-5.8 | 5.8 | 5-7 | |

| SF type flotation machine | SF-0.37 | 0.37 | 0.2-0.4 |

| SF-0.7 | 0.7 | 0.3-0.9 | |

| SF-1.2 | 1.2 | 0.6-1.6 | |

| SF-2.8 | 2.8 | 1.5-3.5 | |

| SF-4 | 4 | 2-4 | |

| SF-8 | 8 | 4-8 | |

| SF-10 | 10 | 5-10 | |

| SF-20 | 20 | 5-20 | |

| JJF type flotation machine | JJF-2 | 2 | 1-3 |

| JJF-4 | 4 | 2-4 | |

| JJF-8 | 8 | 4-8 | |

| JJF-10 | 10 | 5-10 | |

| JJF-16 | 16 | 5-16 | |

| JJF-20 | 20 | 5-20 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat