By Hubery Editer

By Hubery Editer

Looking around, concrete is seen everywhere due to the incorruptibility: road, house, bridge, etc. While for a long-term safety, the concrete will be replaced one day. Therefore, there are annually increasing waste concrete (waste construction concrete) to be disposed.

Usually, waste concrete is dealt by landfill, stacking or other ways, which not only pollutes soil and rivers but also waste land sources.

Waste Concrete

How to recycle such waste efficiently for better economy recycling? Here are 5 kinds of waste concrete recycling machines as a suggestion.

These 5 kinds of concrete recycling machines are mostly used and most popular equipment. The followings are the reasons why you can choose them for recycling waste concrete.

The first part of them is the recycling star: crushing equipment. This kind of machine is divided into mobile type and stationary type.

When recycling waste concrete, most of the working sites are unfixed. Mobile crushing station is the most suitable recommendation for concrete crusher due to its flexibility.

This concrete recycling machine is mainly used for processing materials that often have to be moved. It integrates feeding, crushing, screening and conveying into one, which can eliminate the limitation of the operation site and make the recycling flexible.

Besides, from a view of long term, mobile crusher reduces investment in infrastructure and transportation. It has excellent performance in the production plant of turning construction waste into aggregates.

Configurations of Fote Mobile Crusher

Mobile crushing station is divided into two types: crawler type and wheeled type.

In the recycling of waste concrete, the wheeled crusher can be moved freely by a tractor, which is mainly used in some urban infrastructure, roads or construction sites.

The crawler crushing station is like a small tank, and the chassis is made of all-steel ship structure with higher strength. Such design makes it easier to adapt to the harsher operating environments, and even in some large-scale waste concrete recycling line that needs climbing operation, this concrete recycling machine can show its capabilities.

Advantages of These Two Types of Mobile Crushers

These two mobile crushing machines are especially suitable for waste concrete recycling to complete crushing and screening at one time, providing the required discharge size and capacity.

A whole set of mobile crushing and screening equipment includes primary crushing machine, secondary crushing and screening machine, belt conveyor, etc. All the machines can fulfill their respective responsibilities in the production.

According to different needs, both crawler and wheeled concrete crushing stations can be equipped with different machines, such as sand making machine, jaw crusher, cone crusher, impact crusher, vibrating screen, etc. Each mobile crusher establishes a system of its own, which can be used in the concrete recycling production line alone.

Video of working site of mobile crushers for waste concrete recycling

While some concrete waste concrete recycling sites are relatively fixed. Under such condition, stationary crushers can meet the recycling requirements. And jaw crusher, impact crusher and sand making machine are considerable choices.

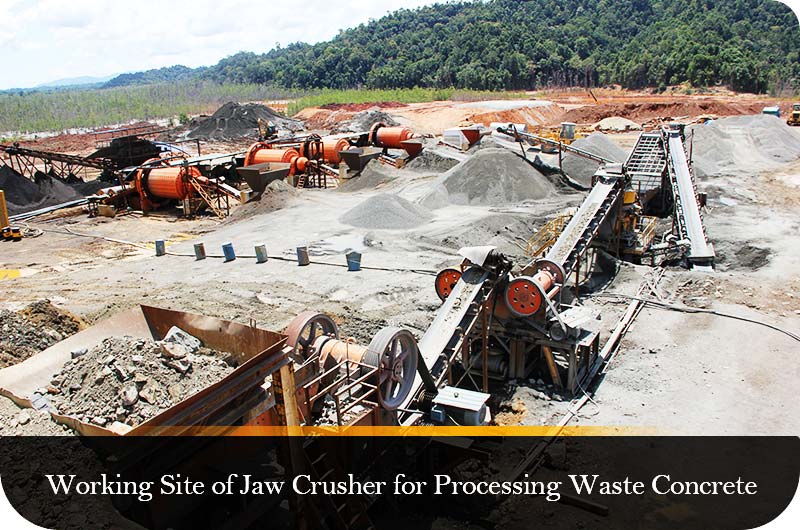

As the most extensively used concrete recycling machine, jaw crusher must have its name on the list. Jaw crusher is usually used as the primary crushing equipment or in the crushing plant that doesn’t need small discharge size.

This "crush-it-all" equipment recycles waste concrete with a high proficiency. The first-class material and excellent process ensure a 20% development of production efficiency. In addition, the discharging is adjusted by the screw, hydraulic pump and the wedge-shaped structure. This facilitates the operation.

As the oldest crushing equipment, the crushing technology of jaw crusher has been improved since its birth. Models of jaw crusher cater to recycle waste construction concrete in various scales of plants.

Working Site of Jaw Crusher For Waste Concrete

Besides, if the waste concrete contains impurities, the toggle plates made of high-strength steel protect the main part from harm and lower the economic loss greatly.

Another concrete recycling machine that has to be mentioned is the impact crusher. This kind of concrete recycling machine can be used as the secondary crusher. It is rather welcome in all kinds of production plants as well as the sole crushing equipment.

The latest generation impact crusher adopts triple-impacting plates inside the cavity. When recycling waste concrete, the impaction to material is increased to 3 times, the abrasion to a single plate is reduced by 3 times and the service life of wearable parts is prolonged.

Fote Impact Crusher

If you need aggregates from waste concrete with different particles, the bolts can be adjusted to change the gap between the impacting plate and hammer head conveniently. This is for having an effective control of the discharge particle size.

Among many models of impact crusher, the PF1315 is equipped with a hydraulic device to facilitate maintenance.

These advantages make impact crusher suitable for handling soft materials a popular option for recycling waste concrete.

Concrete recycling site of impact crusher

Jaw crusher and impact crusher can meet the need for concrete recycling plants with large discharge size, while if small discharge size is needed, it is the show-time of the sand making machine.

The sand making machine, or the sand maker, can work with a primary crusher to turn the waste concrete into artificial sand up to 5 mm.

Common concrete sand making machine has two types of HVI series and VSI series. Like impact crusher, the HVI and VSI sand making machines adopt impaction to break the material, which has the function of shaping and the product size is adjustable.

In addition, if the polishing head is needed to be replaced, the operator only needs to stop the machine and adjust the worn part up and down thanks to the combined design. This design reduces the recycling cost of waste concrete by about 30%.

Sand Making Machine Crushing Waste Concrete

The second part of the most used concrete recycling machine is screening equipment. Screening equipment is a kind of auxiliary equipment, but can also be used alone.

As the name implies, this equipment is mainly used to grade waste concrete with different particle sizes and is also an essential machine in the process of concrete recycling.

When screening equipment is used subsequently, it can be configured on a crushing station. It is used to grade the product from the previous stage and determine whether it is suitable for the next processing.

It connects every link of the concrete recycling, and plays the role of connecting the preceding and the following to guarantee a continuity of production.

When used alone, screening equipment is a sole recycling line in some concrete recycling sites. In these plants, the dismantled concrete only needs to be divided into different sizes of recycled concrete aggregates for different industrial fields.

Screening site of recycling waste concrete

The Benefits of Screening Equipment

Taking the circular vibrating screen, or the round vibrating screen as an example, you can get to know the main advantages of the screening equipment:

Advantages of Vibrating Screen

As some data shows, after 28 days, the setting and hardening of concrete has not completely ended. That is to say, at this time there are still active ingredients in the cement conducive to the hardening of concrete.

If the waste concrete is crushed, pulverized and classified for recycling, there will be a promotion on the strength development of recycled concrete.

With the increasingly mature technology, recycled concrete is more and more widely applied to manufacturing regenerated mortar, cement hollow block, roadbed construction, road surface construction, pavement brick and other construction materials.

And in construction, recycled concrete is mainly used for manufacturing those doesn't need very high compressive strength. These parts can be foundation pad, baseplate, platform, wall filler and other non-structural components.

Applications of Recycled Concrete

1. In waste concrete recycling with crushing machine, we should pay attention to the steel contained in the material. The magnetic separator can be used to separate the waste steel, and then the vibrating screen can be used to screen out light debris;

2. Since the characteristics of waste concrete are different from that of ordinary concrete, recycled aggregate of treated concrete cannot be used in accordance with the ratio of ordinary concrete;

3. Crushing is one of the stages of recycling waste concrete. Depending on the situation, other needed processes can be carried out for recycled concrete, such as grinding, etc.;

4. Recycled concrete generally cannot be used as the only raw material for manufacturing new construction aggregate. There should be professional engineers to carry out experiments to get a suitable material ratio.

International conferences have been held on the recycling of waste concrete. In every country since the Second World War, more and more attention has been paid to waste concrete recycling.

It is for sure that the recycling technology of waste concrete will be more and more mature in the near future.

As a professional concrete recycling machine supplier, Fote Machinery is focus on supplying kinds of equipment to your needs. If you have any questions, welcome to leave a message online or email us at quote@sinoftm.com.

Online Chat

Online Chat