By Fote Machinery Editer

By Fote Machinery Editer

Granite, basalt, bank gravel, bauxite, cement clinker, quartz silicon carbide,limestone, river stone, etc in hydropower, building material, highway, city construction, metallurgy, coal mining and so on.

Production Capacity: 50-800TPH

Configuration:Jaw crusher, impact crusher, vibrating feeder, vibrating screen, conveyor and so on.

The main components of basalt are silica, aluminum trioxide, calcium oxide, magnesium oxide (as well as a small amount of potassium oxide, sodium oxide), in which silica content is the most, accounting for about 45% to 50%.

Basalt is the best material for repairing roads, railways and airfield runways. It has the advantages of abrasion resistance, less water consumption, poor conductivity, strong compressive strength, low crushing value, strong corrosion resistance and asphalt adhesion, which is the best cornerstone for the development of rail transport and road transport. Basalt is widely used in the chemical industry, wear-resistant materials, insulation materials, civil air defense engineering, and other fields. Because of the large size of the mined basalt materials, it is often necessary to crush them into small pieces and then being used in the actual production process

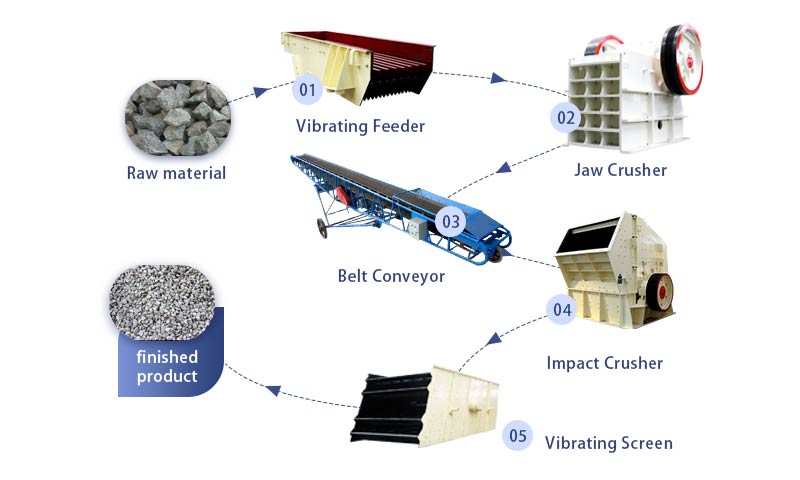

The crushing production line equipment equipped by our technical experts for basalt processing is mainly composed of jaw crusher, impact crusher, vibrating feeder, vibrating screen, conveyor and so on. The specific model size should be selected according to the actual production situation and production requirements. The following is a brief introduction to the characteristics of the main equipment used.

Jaw crusher is an indispensable coarse crushing equipment in basalt crushing production line. It is a basalt crushing equipment with wide application range and high sales volume in the market at present. Compared with the same type of jaw crusher on the market, the equipment mainly has the following three outstanding advantages: ultra-high crushing efficiency, super adaptability, ultra-low production cost.

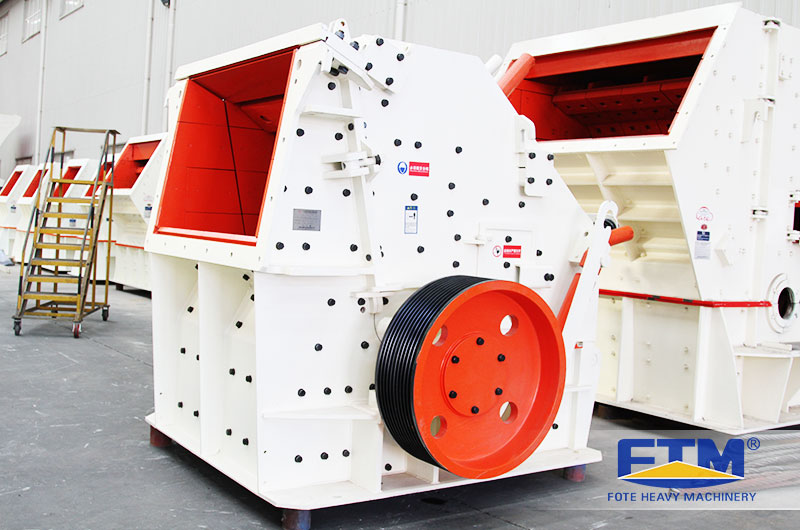

The impact crusher is used for the secondary crushing and processing of basalt. The great advantage of this equipment is that the structure design is very reasonable, the area occupied is only 1/2 of the same type of equipment in the market, the weight is also relatively light, the movement is more flexible, and it can save a lot of capital construction cost and transportation cost for the processing plant. It is favored by the basalt crushing plant.

Vibrating feeder plays a uniform feeding role in basalt crushing production line. It has many unique advantages, such as fast feeding speed, easy operation, low power consumption, stable operation and so on.

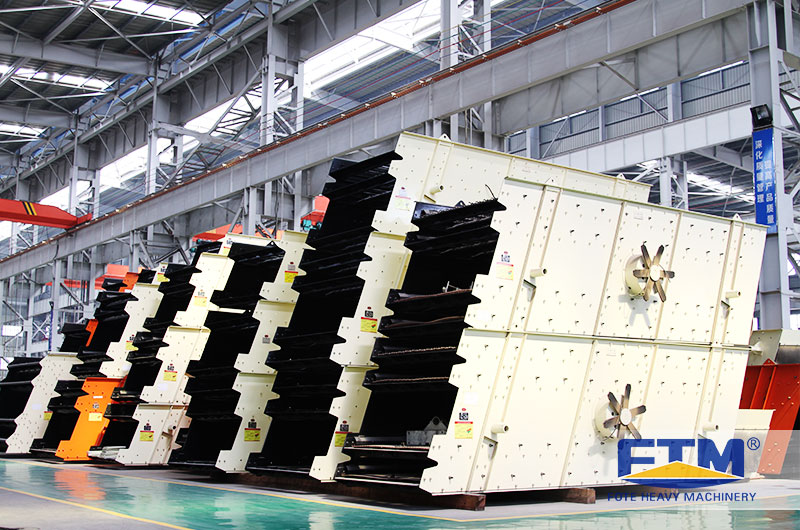

Vibrating screen plays the role of screening and grading in basalt crushing production line. It can screen basalt into different particle size grades, which has the advantages of flexible adaptation, high screening efficiency, low cost and so on. Moreover, the price of this equipment is also very economical and affordable, and it has a high share in the market.

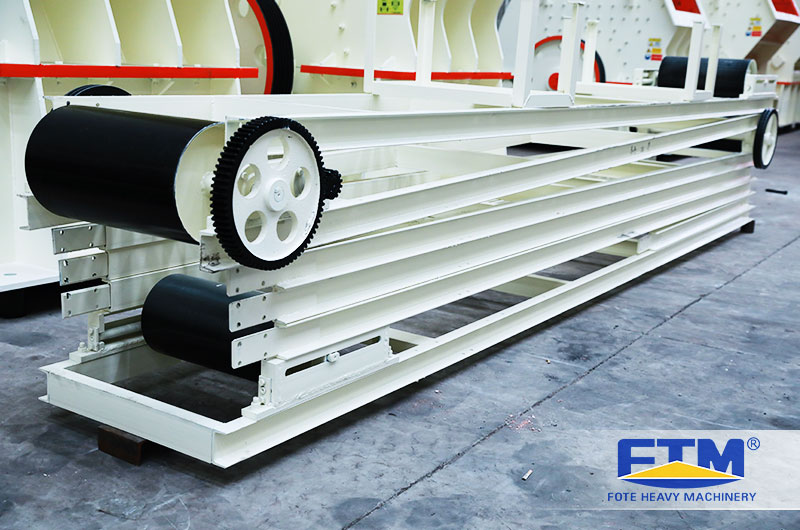

The conveyor acts as the transportation function in the basalt crushing production line. Compared with the transportation equipment produced by other manufacturers, the processing capacity of the equipment to basalt is increased by more than 40%, and the transportation efficiency is increased by 40% and 50%, which is favored by the majority of users.

First, the original basalt ore is uniformly and continuously sent into the jaw crusher through the vibrating feeder for a certain period of time crushing, and the basalt after rough crushing is sent to the impact crusher for secondary crushing through the conveyor. And then basalt materials sent by the conveyor to the vibrating screen, which is divided into different grades, and the basalt materials that meet the requirements are sent to the finished material pile. Basalt materials that do not meet the requirements are returned to the impact crusher for re-crushing, so that they go back and forth until they meet the requirements.

For more details and price of basalt crushing plant, please click online customer service, we will customize professional production plan for you.

To sum up, the basalt crushing production line designed by our factory has reasonable equipment configuration and excellent technological process, which plays an important role in reducing the production cost and improving the economic benefit of the basalt processing plant. New and old users are welcome to come to inspect and purchase. For more details and price of basalt crushing plant, please click online customer service, we will customize professional production plan for you.

Online Chat

Online Chat