By Hubery Editer

By Hubery Editer

In present market, there are mainly air-flow dryers, mesh belt dryers and rotary dryers, the last type of which includes single-cylinder dryer, double-cylinder dryer and three-cylinder dryer. Among them, the structure of rotary dryer, especially single-cylinder dryer, is the simplest, so it is the most convenient to operate and maintain rotary dryers. Excluding the one-time investment, the following repair and maintenance costs are relatively low. Generally speaking, the rotary dryer is more recommended to customers.

The rotary dryer takes advantages of the heat exchange between scorching wind and the material to decrease the water content of materials. This is for the purpose of applying it directly into the next production, for which the rotary dryer is a rather effective drying equipment. In addition to the simple structure and the low cost, its strong adoptability makes it play an essential part in all kinds of industrial process.

Fote Rotary Dryer

Different types of rotary dryers work the backbone role in different fields. How should customers select the right rotary drying machine based on their requirements?

As for the difference on the structure and processing environment, diverse rotary dryers can be used for drying different materials and in different plants. Besides, more attention shall be paid to the following factors when choosing a suitable rotary dryer. Customers should offer the project details including required capacity, feed moisture, and discharge moisture needed, etc.

Material need to be dried takes the leading position in these factors. As different materials have different properties and even materials of different sources have different properties, specially designed rotary dryers are needed.

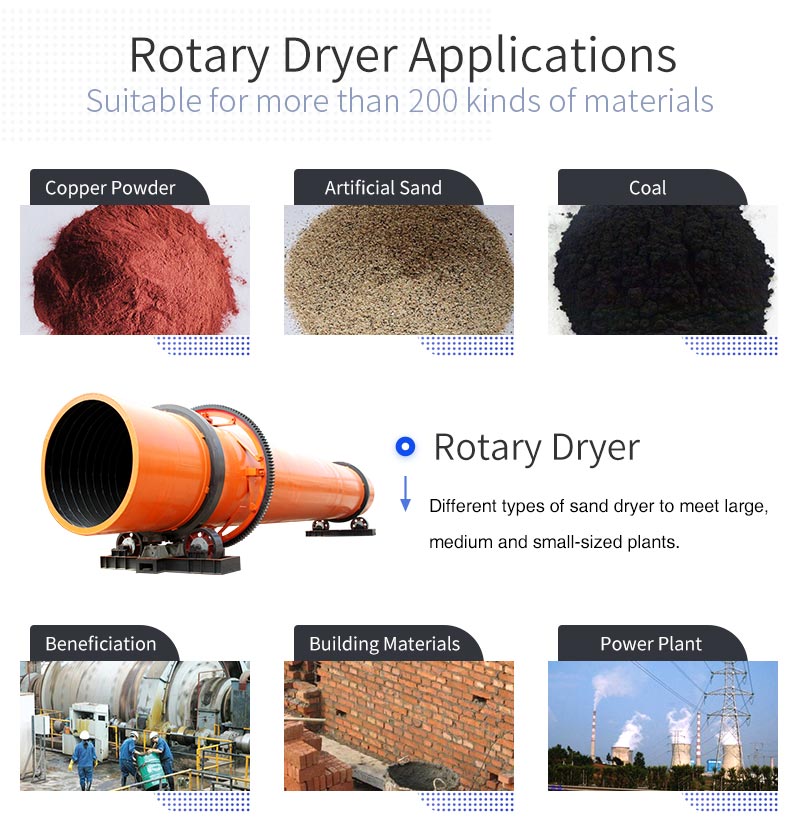

Applications of Rotary Dryer

Ore powder generally refers to the powder obtained by crushing the extracted ore. There are some examples of ore that will be separated by flotation method.

a) non-metallic minerals and silicate minerals like graphite, quartz, feldspar;

b) non-metallic salt minerals like fluorite, apatite, barite;

c) soluble salt minerals potassium like salt, rock salt.

To maintain the physical property of the ore powder, ore powder rotary dryer is needed to dewater the high-moisture ore powder at a high speed with high temperature. It is easy to store and transport dried ore powder.

Fly ash is collected from the fumes and smoke of the burnt coal mainly in thermal power plant and urban centralized heating boiler etc. Over 90% of the exhausted fumes and smoke are wet with about 45% humidity. As the fly ash is light, the fly ash dryer is designed to reduce the strength of the blower to narrow blocking to the drying cylinder.

| Fly Ash | |

| Main Source | Thermal power plant, urban centralized heating boiler,etc. |

| Main Oxide Composition | SiO2, Al2O3, FeO, Fe2O3, CaO, TiO2, etc. |

| Moisture | About 45% |

The dried fly ash can be used as raw materials of cement and concrete, or in the production of building materials, such as steaming fly ash brick and so on.

The slurry has the characteristics of high-water content and high viscosity. When design slurry dryer, engineers should pay more attention to the bonding when the material enters the drying cylinder. Slurry dryer is designed to make a full use of lifting plates and the burner according to slurry property.

>>1. in the feeding port, burner is used to rapidly dry the surface layer of high-moisture slurry, and the bonding phenomenon is reduced;

>>2. then the spiral-shaped plates will break the material and increase the heat contact area to enlarge the drying efficiency.

Therefore, when contacting the rotary dryer, it is necessary to know the relevant project information in advance, especially the specific details of the material so that the engineer can offer the appropriate solution. If possible, engineers can be asked to inspect the operating environment and give professional model selection suggestions.

The rotary dryer recycles part of the hot air, saving energy and reducing cost. But the main heat sources can be coal, natural gas, and steam boilers. Customers can choose different fuels according to their needs.

In view of the important backbone function of the rotary drum dryer machine, to select a professional rotary dryer manufacturer becomes rather important. How should investors choose a professional and reliable rotary dryer manufacturer? Here are some key factors for your reference.

The strength of a factory can be reflected by its production scale. The large production scale not only indicates that the production capacity of one manufacturer is in the leading position, but also reflects the manufacturer's professional production line from the side, and has a certain competitive power. In addition, large-scale production indicates that the manufacturer has a certain development history and can ensure the integrity of the overall service.

Fote Machinery Factory

The high-quality manufacturing here means not only the manufacturing process but also the high quality of the material used in the rotary dryer production. Although the rotary drying machine is simple in structure, the shafts bearing or rolling wheel used for bearing the load of the whole machine, the rolling ring, the main rotary dryer parts, the drying cylinder and the like should be paid attention to the details of production.

For example, the shafts bearing or rolling wheel production shall be focused on balancing rotary dryer cylinder weight and the smooth operation during the working process. The gear of the rolling ring needs to be matched with the riding wheel to promote the operation of the main rotary drum dryer body. And the production of the main part, drying cylinder, needs more attention to the factors such as the sealing effect, the drying efficiency and the adaptability to the material characteristics, etc.

In addition, since the rotary dryer is utilized to dewater large-moisture materials, the material that used to produce the rotary drying machine needs a more careful selection. The selected material shall be strong enough and be resistant to corrosion to extend the service life of the rotary dryer.

Fote Engineers are Inspecting Finished Competent.

We often hear rotary dryer manufacturers provide one-size-fits-all product services. This scheme sounds like an attractive and cost-effective solution. While this seemingly omnipotent solution will show its disadvantages when it is really implemented. That all the materials are dried in one machine does not really take all the factors into account, which can improve the drying efficiency and save the operation cost.

Factors like material properties, processing environment and required final product characteristics are important factors for customized rotary dryer design and calculation to achieve the best drying efficiency. Besides, rotary dryer capacity is based on cylinder length and the diameter.

Other adjustable factors are airflow direction, cylinder structure, prevention inclination and so on, which can be used to improve drying efficiency to the maximum extent. The flexibility of the rotary drum dryer design and customization is an essential aspect of choosing the right manufacturer that meets your unique processing requirements.

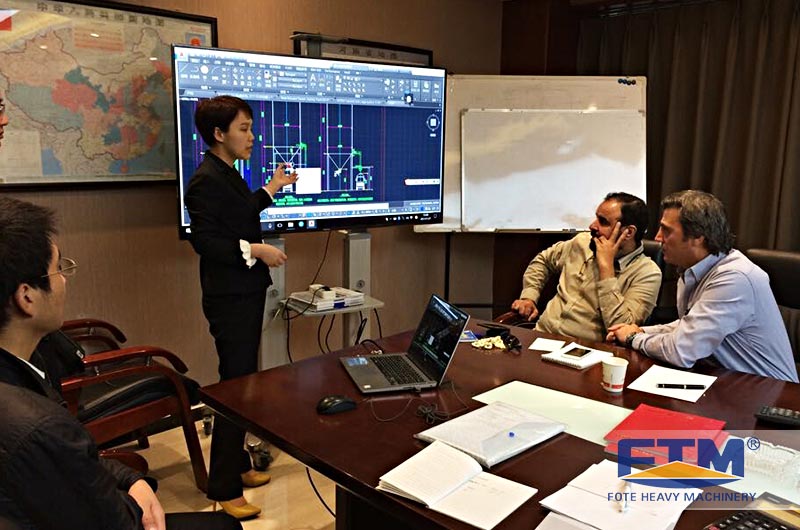

Engineer is introducing Fote product to customers.

Regular rotary dryer manufacturers solutions should be professional and complete.

Professional solution refers to the rotary dryer engineer can provide solutions according to the customer's on-site working environment and engineering requirements. In addition, they shall have an intimate knowledge of all kinds of material characteristics, but also be familiar with the materials to be dried by the customer; even the material characteristics of different sources will be different.

Therefore, when providing solutions for customers, professional engineers will consider the bulk density, water content, specific heat and other factors, and provide customers with material testing service. Manufacturers who provide testing facilities have special value because they can test material properties throughout the process. In addition, they can test various configurations of equipment to achieve the desired results, testing materials throughout the development process.

Discussion between Fote workers in Production

Complete solution refers that rotary dryer manufacturers will continue to follow up from the service, to the provision of solutions, and to the production and manufacture. The integrity of the service is reflected in the pre-sale consultation, in-sale selection and customer site visit, and after-sale feedback tracking, professional manufacturers will spend time and effort to get in touch with the customers. The integrity of production and manufacturing is reflected in the ability of rotary dryer manufacturers to provide the whole drying production line and can provide other targeted equipment according to customer needs.

Rotary dryer has a simple structure and convenient operation, so the following maintenance cost is relatively low. However, the corresponding maintenance is also very necessary. On the one hand, it can prolong the rotary dryer service life; on the other hand, it can improve the drying efficiency. Professional rotary dryer manufacturers should offer customers with the operation training plan, installation guidance, maintenance plan, spare parts knowledge and other services.

Fote After-Sale Support Team

In the professional after-sales service, timely emergency plan is the strong support for the customer. Although the running failure rate of rotary dryer is very low, when there is a sudden problem, the manufacturer can provide the scientific emergency plan to the customer in time or in advance, which can minimize the loss of customers and reflect the professionalism of a manufacturer.

It is not easy to choose a professional rotary dryer manufacturer in the broad mining machine market. However, the right rotary dryer manufacturer can offer a suitable rotary dryer machine to improve the drying efficiency in the next processing program. This is a guarantee of improving the processing ability of the whole production line.

Fote Rotary Dryer Customer Site

Therefore, when choosing the rotary dryer manufacturer, customers should take compressive factors into consideration including the production capacity of the rotary dryer manufacturer, the flexibility of the provided solutions, the professionalism of the product and material knowledge, the scientific nature and timeliness of the service and so on.

For over 40 years, Fote has been working on the rotary dryers’ design and manufacture. Our rich knowledge of material processing combined with our testing facilities enables us to provide customers with the best drying solutions. In addition, our experienced technicians can serve you to prolong the rotary dryer service life. Welcome to chat online with our staff at any time to get the latest factory price.

Online Chat

Online Chat