Rotary dryer is one of the most used dewatering equipment, which is to reduce certain moisture of the material in industrial fields. For its drum design, it is also called drum dryers sometimes. As industrial dewatering equipment, the rotary dryer has an increasingly optimized structure with the development of industrial development.

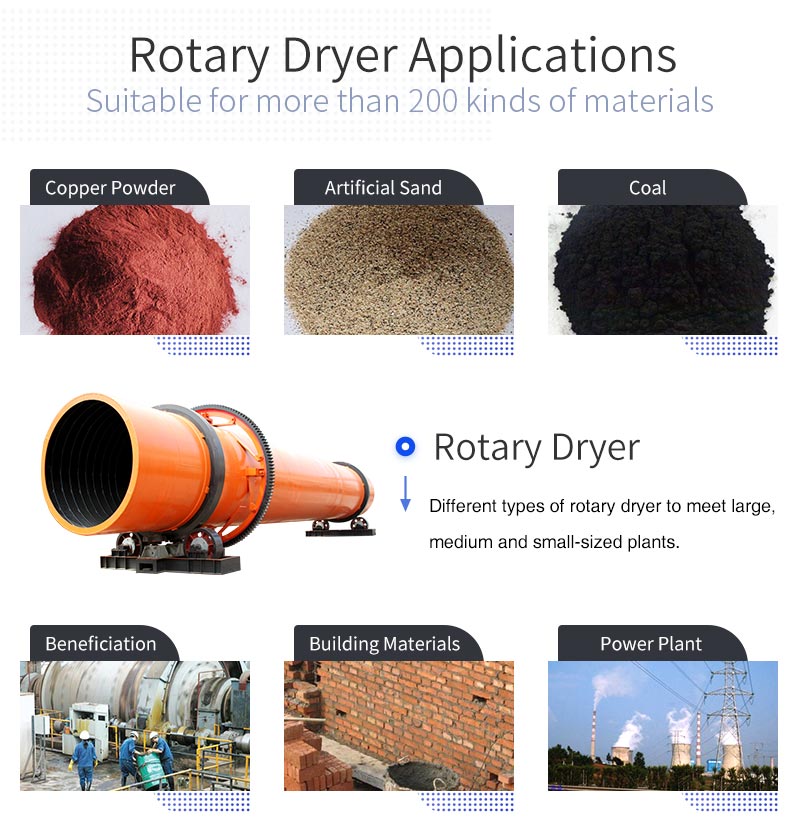

Improved dryer machines can meet various requirements of materials, like fly ash, kaolin, silica sand, gypsum, iron sulfide, coal, sawdust, slag, limestone, etc.

As is a professional rotary dryer manufacturer, Fote keeps the optimization of our rotary dryer and have formed our series. We provide various plants with types of drying equipment.

Fote Rotary Dryer

With the development of drying technology, the structure of the rotary dryers is optimized and simplified. At present market, each part of rotary dryers plays its role to improve processing efficiency.

Rotary dryers have a horizontal structure. The main body is the drying cylinder rotated by gears. This part includes feeding port, discharge port and the cylinder.

※Spiral feeding plate is equipped at the feeding port for more convenient material feeding.

※The discharged port is provided with a material-holding ring. This is to prevent the disqualified material from being thrown out.

※Inside the cylinder, lifting plates are welded on the inner wall. According to the requirements, the plates can be welded into 90°, 135°, 150° and other angles and produced into different shapes.

What supports the drying cylinder is the supporting device consisting of a wheel belt, supporting wheel and thrust rollers. Wheel belt is covered on the cylinder of rotary dryers and supported by wheels. Same as the supporting wheels, the thrust rollers are set on the rack. Two thrust rollers are playing the function of controlling the axial movement of the cylinder within 5mm.

To smooth the running of the supporting device and lower the temperature produced during the processing, the holder is filled with water and oil, of which the oil can be waste.

The driving device has a similar principle to other machines. The rotator is driven by a triangle belt, big gear, small gear and reduction gear to move the cylinder.

Here is a video to find out how the supporting device bears the cylinder and how the gears run.

Video of Fote Rotary Dryer Running at Working Site

What is worth being mentioned is the sealing plates. Fote rotary dryers usually have hundreds of stainless-steel plates at the joints of feeding port and cover and of the discharging port and cover. The number of plates varies based on the model.

Stainless steel has good elasticity and heat resistance. Besides, stainless steel is of perfect followability and adaptability to the cylinder bounce in the rotating. This design reduces heat loss to the maximum and improves drying efficiency.

This type of dewatering equipment is extensively applied for drying particles and granules no more than 5mm. If the material is too large, a small crusher machine is suggested for the first breaking.

With the strong adaptability, we can see it in cement plant, coal industry, mines, building material production and other industrial fields.

For example,

◆ In cement plants, rotary dryers are used for dewatering fly ash, pozzolana, etc. to meet the requirements of cement production;

◆ In the recycling field, rotary dryers can be used for drying sludge and other similar waste. Such waste contains rich organic matters, which can be recycled as fertilizer.

◆ In mine, rotary dryers are mostly used in the ore beneficiation plants after the wet grinding process. The rotary dryer can dry the ore pulp after the pressure filter to get the fine powder.

Examples of Rotary Dryer Applications

Given different structures and applications, the rotary drum dryer is divided into several types. And thus, drying technology is more targeted.

According to the structure, rotary dryers are divided into the single-cylinder type and multi-cylinder type.

Based on experience and customer feedback, Fote engineers will recommend the single-cylinder rotary dryer. These two types of rotary dryers have almost the same drying efficiency. While the structure of the single-cylinder one is simpler, resulting in more convenient daily maintenance. The maintenance personnel can directly get into the cylinder body for inspection. For multi-cylinder dryers, this is difficult to achieve.

Working site of single-cylinder rotary dryer and multi-cylinder rotary dryer

According to the heat transfer mode, the rotary dryer is divided into the direct type and indirect type, or it can also be divided into a co-current rotary dryer and counter-current rotary dryer.

Among them, the co-current rotary dryer and direct dryer are the most widely used. If the material quality is too small, to prevent material flowing back and cannot be dried, the co-current type must be used.

However, due to different materials and drying requirements, in the following cases, Fote engineers will also recommend counter-current rotary dryer and indirect one.

※When the moisture requirement of the product is below 5%, the higher drying efficiency of the countercurrent drum dryer can meet the more stringent drying requirements.

※Indirect heat transfer dryers are an option to prevent contamination of materials in contact with smoke or fire from direct combustion.

Each type of rotary dryers has the same working principle on the gravity and heat exchange. A brief introduction to the rotary dryer processing principle is given taking the counter-current rotary dryer as an example.

From figure-1 you can see that in the counter-current cylinder, the material moves in the opposite direction to the hot air. This is the main difference between counter-current type and co-current type.

The rotary dryer is placed horizontally at an angle of 5°. The material is sent into the dryer cylinder. With the rotation of the dryer, the material is lifted down by the plate, moving forward. The hot air coming in from another end is met head-on.

In the rotation and advance, the heat exchange is finished between the material and the hot air, and the water is taken away. The calculated cylinder length is just enough to dry the material to the required moisture and then the material is discharged from the outlet.

Figure-1. Rotary Dryer Working Principle

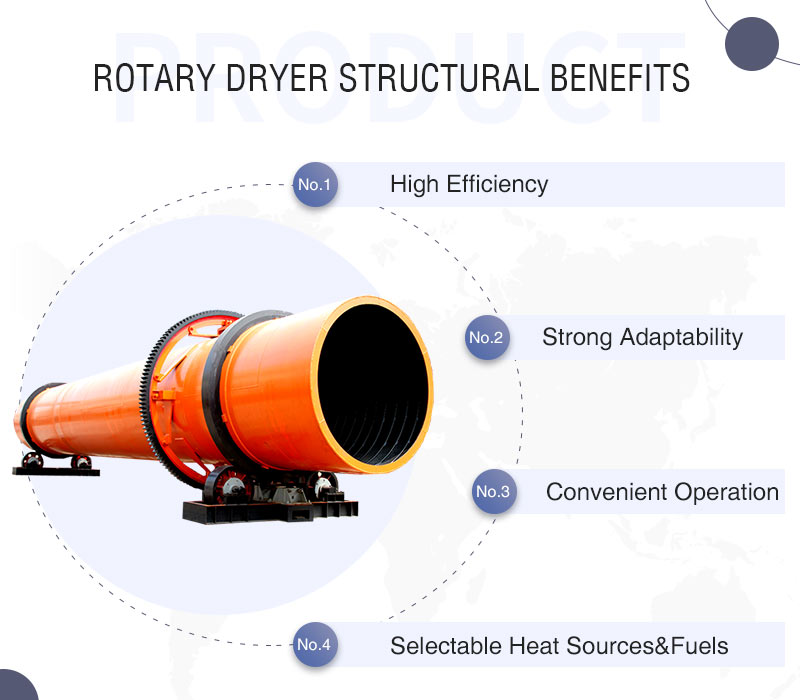

Although Fote offers rotary dryer with simple structure, considering that our customers are from small, medium and large factories, our dryer machines have the following advantages:

Benefits of Rotary Dryer

The Indonesian customer bought a clay drying line from Fote. He was introduced by a friend and contacted our engineer via WhatsApp. After several rounds of discussion, Eric provided him with a solution that met the drying requirements and saved costs.

The main information on the drying line is provided for reference only.

Processed material: clay

Capacity: 20TPH

Feed moisture: 34-40%

Discharge moisture: 2-5%

Fote Rotary Dryer in Indonesia

Customer feedback: Thanks for Eric's professionalism and patience. Our drying line was put into production within one month after we got the plan. This greatly shortens the cycle of cost recovery. Fote engineers also provided us with on-site installation guidance and operator training. We also got a one-year warranty, but we didn't have a chance to use it.

Fote Rotary Dryer Shipment

Although the rotary drum dryer has a simple structure, and different parts ensure drying efficiency, to achieve satisfactory drying results, it is necessary to get a reliable drying flowchart from experienced manufacturers.

As a professional rotary dryer machine manufacturer, Fote Machinery has particularly mature dewatering technology, and satisfactory solutions have provided to various customers. We have professional engineers to offer customized drying solutions, a specialized factory and seriously experienced operators for the production of the quality guaranteed product. Besides, we have a professional and timely product after-sales service team.

From customized drying solution to preferential dryer prices and then to satisfactory after-sales service, Fote deserves your trust.

Fote service provided to customer

Welcome to contact our skilled sales personnel online or email at quote@sinoftm.com to get the latest quotation and discount

Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity (%) | Highest Inlet Air Temperature (℃) | Main Motor (kw) | Weight (t) |

Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items | Inside diameter of outer shell (mm) | Inside diameter of inner shell (mm) | Shell Length (m) | Shell cubage (m³) | Shell obliquity | Lifting blade form | Highest inlet air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) |

Φ1.2×8.0 | 9.0 | 1.9~2.4 |

Φ1.2×10 | 11.3 | 2.4~3.0 |

Φ1.5×12 | 21.2 | 4.5~5.7 |

Φ1.5×14 | 24.7 | 5.3~6.6 |

Φ1.5×15 | 26.5 | 5.7~7.1 |

Φ1.8×12 | 30.5 | 6.5~8.1 |

Φ1.8×14 | 35.6 | 7.6~9.5 |

Φ2.2×12 | 45.6 | 9.7~12.2 |

Φ2.2×14 | 53.2 | 11.4~14.2 |

Φ2.2×16 | 60.8 | 13.0~16.2 |

Φ2.4×14 | 63.3 | 13.5~16.9 |

Φ2.4×18 | 81.4 | 17.4~21.7 |

Φ2.4×20 | 90.4 | 19.3~24.1 |

Φ2.4×22 | 99.5 | 21.2~26.5 |

Φ2.6×24 | 127.4 | 27.2~34.0 |

Φ3.0×20 | 141.3 | 30.1~37.7 |

Φ3.0×25 | 176.6 | 37.7~47.1 |

Φ3.2×25 | 201 | 42.9~53.6 |

Φ3.6×28 | 285 | 60.8~76.0 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items | Inside diameter of outer shell (mm) | Inside diameter of inner shell (mm) | Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat