To recycle slag produced in ore dressing or smelting industry, Fote Machinery develops new advanced dryer for slag drying. FTM slag dryer machine is commonly used in building materials, chemical industry, cement, etc. Mainly composed of rotary cylinder, lifting blades, self-cleaning device and other equipped devices, slag dryer, or slag drying machine operates stably as well as is of mature technology, high production capacity and efficiency.

√ High temperature fluidized furnace

√ Pulverized coal duster furnace

√ Artificial coal furnace.

Thanks to its own cleaning device and material lifting plate, slag dryer is extensively applied to dewater wet materials with large specific gravity.

Applied Fields of Slag Dryer

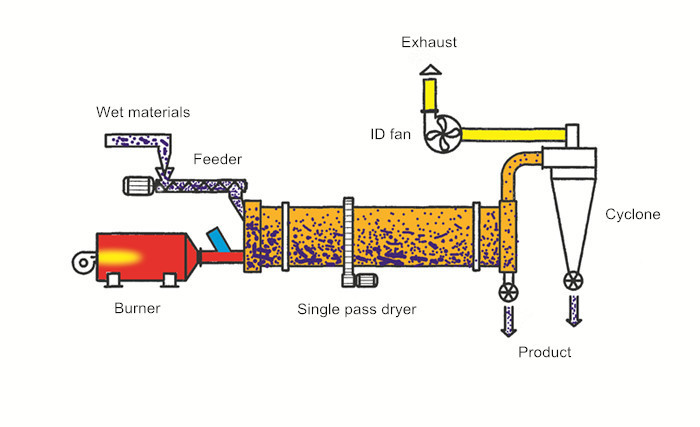

Co-current heating mainly works in slag drying process. Wet slag is transmitted into the cylinder by the feeding box and feeding conveyor. Then it is pushed back to the other end of the cylinder of the drum by spiral blades inside. The dryer is set at a certain angle. On one side, the wet slag flows down to the exit under the effect of gravity and rolling. On the other, it is brought up to the top end of the cylinder by the blades and falls into a screen to get in full touch with the scorching wind. Thanks to this repeated proceeding, wet slag is dried step by step.

Working Principle of Slag Dryer

Slag dryer is also a kind of rotary dryer, which is mainly composed of a rotating cylinder, induced draft fan, high-speed scattering equipment, lifting plates, self-cleaning device, transmission device, conveyor, hot air equipment, reducer, supporting device, sealing device and other components.

Structure of Slag Dryer

The key to extend the service life of the slag dryer is to do often maintenance and check. Based on experience, Fote engineers give some tips for reference.

1, Bearings take all the load of the machine. Therefore, satisfactory lubrication is much concerned with the service life. Lubricant oil infused shall be clean and the container shall be sealed well;

2, Frequently check the newly installed tyre, which is easily loosed;

3, Pay more attention to the easily-worn parts and be ready to replace those need to;

4, Pay much attention to the oil temperature of the bearing parts. Put an end to the dryer immediately, if it goes up higher. Find the cause and figure it out.

5, An impacting sound from the rotating wheels shall call your attention to stop this drying machine. Immediate check and solutions are needed.

In India, Fote slag dryer machine is used in cement plant. The customer got the contact from his friend and searched on the net. He saw our web of slag dryer and chatted with our skillful engineer online. And in about 24 hours, he got an email enclosed with two customized solutions including the slag dryer price, the production line flow, etc.

Being pressed by quick reply and professional suggestions from Fote engineer, he paid a visit to our factory and introduced the drying line from Fote Machinery. The followings are the details of this production line.

Capacity: 50TPH

Feed moisture: about 30%

Discharge moisture: 1-1.5%

Use of the dried slag: raw material in cement production

Our Indian Customer with FTM Engineer

Located in Zhengzhou, China, the mining machinery center, Fote Machinery is a professional slag drying equipment manufacturer in China, who has various slag dryer for sale like steel slag dryer, granulating slag dryer, etc. Our engineers have advanced international technology as support and are specialized in designing and producing slag dryer based on your need. Customers are warmly welcomed to chat online with the skillful engineer for slag dryer price and the production flow!

Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity (%) | Highest Inlet Air Temperature (℃) | Main Motor (kw) | Weight (t) |

Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items | Inside diameter of outer shell (mm) | Inside diameter of inner shell (mm) | Shell Length (m) | Shell cubage (m³) | Shell obliquity | Lifting blade form | Highest inlet air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) |

Φ1.2×8.0 | 9.0 | 1.9~2.4 |

Φ1.2×10 | 11.3 | 2.4~3.0 |

Φ1.5×12 | 21.2 | 4.5~5.7 |

Φ1.5×14 | 24.7 | 5.3~6.6 |

Φ1.5×15 | 26.5 | 5.7~7.1 |

Φ1.8×12 | 30.5 | 6.5~8.1 |

Φ1.8×14 | 35.6 | 7.6~9.5 |

Φ2.2×12 | 45.6 | 9.7~12.2 |

Φ2.2×14 | 53.2 | 11.4~14.2 |

Φ2.2×16 | 60.8 | 13.0~16.2 |

Φ2.4×14 | 63.3 | 13.5~16.9 |

Φ2.4×18 | 81.4 | 17.4~21.7 |

Φ2.4×20 | 90.4 | 19.3~24.1 |

Φ2.4×22 | 99.5 | 21.2~26.5 |

Φ2.6×24 | 127.4 | 27.2~34.0 |

Φ3.0×20 | 141.3 | 30.1~37.7 |

Φ3.0×25 | 176.6 | 37.7~47.1 |

Φ3.2×25 | 201 | 42.9~53.6 |

Φ3.6×28 | 285 | 60.8~76.0 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items | Inside diameter of outer shell (mm) | Inside diameter of inner shell (mm) | Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat