Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Slurry, raw coal, flotation clean coal, mixing clean coal, kaolin, slag, clay, bentonite, limestone, sand, quartz stone, metal concentrate, waste residue and tailings, etc. in mining, ore beneficiation, construction materials and chemical engineering and so on.

Slurry dryer is one kind of rotary dryer specialized in drying various slurry, including coal slime, which can be called coal slime dryer. Besides, it is utilized for the drying of sludge, the metal and nonmetal ores, clay in the cement industry, etc. Slurry dryer adopts the unique scattered device, which can scatter the bonded slurry and then come to the drying process.

It enlarges the contact area between the slurry and hot air, and the heat utilization rate can be significantly improved. The humidity of the slurry can be reduced by 50-80% after drying, which can be directly used. So, we can say that slurry dryer can turn waste into treasure. In addition, slurry dryer is of considerable production capacity. For example, coal slime dryer can effectively solve the reuse problem of slime with a processing capacity of 200 tons, 300 tons, 500 tons, 800 tons, 1000 tons, 1200 tons, 1500 tons and 2000 tons of coal slime. The R&D and production of slime drying machine is the most effective way to the recovery and utilization of coal slime.

Fote Dryer at Customer Site

The efficient energy-saving slurry dryer is a new kind of drying machine developed on the basis of rotary dryer, which can be widely applied to the following fields:

>> The drying of coal slime, raw coal, coal flotation concentrate, mixed coal and other materials in the coal industry;

>> The drying of blast furnace slag, clay, limestone, sand, quartz stone in construction industry;

>> All kinds of metal ore, and tailings of ore dressing industry;

>> Non-thermally sensitive materials in the chemical industry.

Slurry Dryer Application

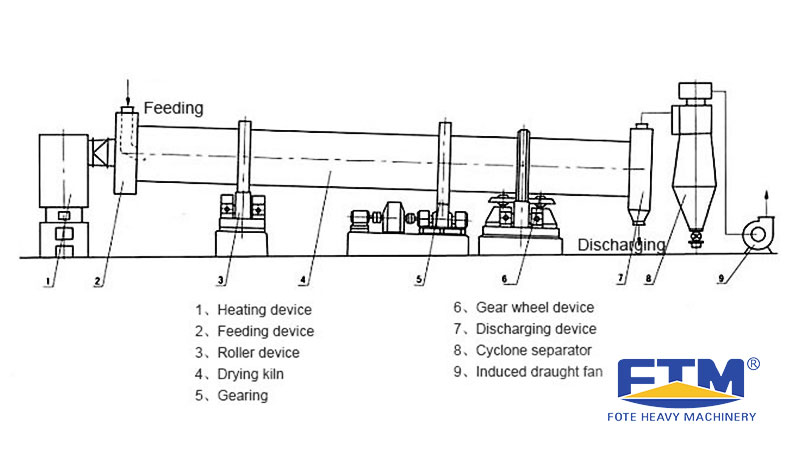

Slurry dryer is mainly composed of heating system, feeding system, transportation system, drying system, dust removal system, induced draft fan and electric control system. As slurry dryer is especially for drying high-humidity materials, the feeder is designed with a scattering function. The cylinder is set at a certain angle. When the slurry dryer works, the feeder firstly scatters the sticky material with double-axis circular pushing process. Based on heat exchange, scorching wind from the fan takes away the water in the material, which is rotated forwards spirally by the lifting plates under the gravity effect. Gradually, the wet material is dried to qualified humidity.

Structure of Slurry Dryer

Fote Slurry Dryer Ready for the Shipment to Customer

There is always a running-in period before the first operation of slurry dryer, usually for 3 days, which is to ensure the normal operation in the following manufacturing process, to lower the failure rate and to extend the service life. Therefore, more attention shall be paid to the first operation.

Firstly, the operator shall be trained before the running-in period on the structure, operation, and solutions to the usual problems. Besides, he or she shall be familiar with the manual. Secondly, in the running-in period, more checks shall be paid to the lubrication, cooling and sealing function, braking and so on. In addition, the operator shall follow the instructions for proper operation and maintenance. The dryer machine workload should not exceed 80% to avoid overheating of drying equipment. Third, be noted that at the end of the running-in period, you should check and replace each part and maintain the dryer machine.

In Ghana, FTM slurry dryer is used with a capacity of 10TPH, input humidity of around 80% and output humidity of 2-4%

Slurry Dryer at Customer Site in Ghana

Fote Machinery is specialized in producing various sizes of slurry dryers, which has high quality, reliable performance and price, and considerate after-sales service. With these advantages, our products have won great support from customers.

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

Installation

Obliquity (%) |

Highest Inlet

Air Temperature (℃) |

Main Motor

(kw) |

Weight

(t) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity |

Lifting blade form |

Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat