By Hubery Editer

By Hubery Editer

River stone, also named gravel or pebble, has excellent hardness and wear-resistance, stable chemical property as well as good compression and corrosion resistance. Besides, it is easily obtainable with a simple sand making process and high-value production. Therefore, river stone is always as the raw material for construction.

We go to get river stone sand from the sand making machine after crushing, screening and other processes. The processed river stone is usually used in concrete widely for road construction, building, bridge construction, water conservancy and hydropower and other fields.

Perhaps some people will ask, artificial sand is likewise a kind of sand and why is it the replacement of natural sand? Isn't it more convenient to use the exited sand, natural sand, which also reduces the cost of sand making machine?

The artificial sand produced by sand making machine has more advantages in terms of both material properties and reserves:

First, in terms of the material property. artificial sand has a more irregular particle. This results in better adhesion and pressure resistance and longer service life than natural sand. Besides, artificial sand comes from specific ore, and there are few impurities.

Secondly, as it is known that various countries have paid increasing attention to infrastructure, the demand for construction raw materials is improved with it. A warning light of natural sand reserve has been on. To protect the environment, governments have restricted the exploitation of natural sand. While artificial sand is got from various stones or even construction waste.

To some extent, the substitute for natural sand is a matter of nature.

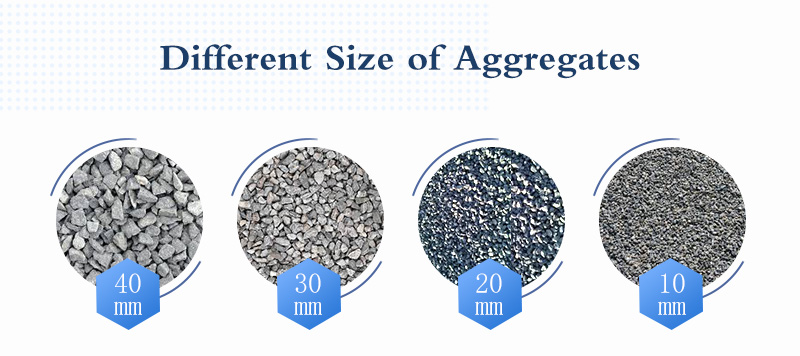

Different size of aggregates

Now that artificial sand is gaining more and more popularity in the aggregate market, what sand maker machines are used in a complete sand production line?

Taking the common river stone, which is also called pebble, as the raw material, here is an example of river stone sand making flow chart and the plant one-time cost in Philippine introduced by Mr. Duterte.

Processed material: river stone (pebble)

Feed size: 40-50cm

Discharge size: 0-5mm

Capacity: 100-150TPH

| 150TPH river stone/pebble sand making plant-main machines | ||||

| Number | Product | Model | Quantity | Power (KW) |

| 1 | Jaw crusher | PE-600x900 | 1 | 55 |

| 2 | Cone crusher | GYS-300 | 1 | 90 |

| 3 | Sand making machine | VSI-8518 | 2 | 180*2 |

| 4 | Sand washing machine | XS2611 | 2 | 5.5*2 |

| 5 | Vibrating screen | 2YK-1848 | 2 | 11*2 |

| 6 | Vibrating feeder | ZSW-380x95 | 1 | 11 |

Note: in addition to the above configuration, types of sand making machines can be combined according to different technological requirements, and different flow charts of river stone sand making production line can be configured.

Customer site of river stone sand making plant

The sand making machines mainly used in the Philippine river stone sand making plant are crushers, sand makers, sand washer and other auxiliary equipment. In the production of river stone sand, jaw crusher and cone crusher are used as the crushing pioneer to crush too large river stones into smaller particles to meet the size of sand maker feed port.

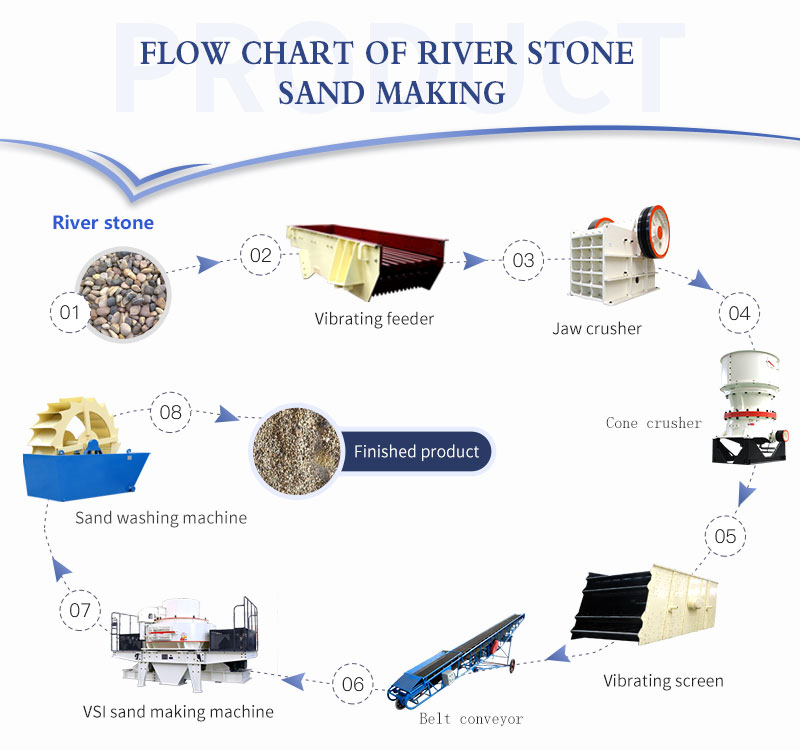

1. The vibrating feeder feeds the river pebble into the jaw crusher and cone crusher. Materials discharged from the jaw crusher are of about 40mm and those discharged from cone crusher are of about 10-20mm, which meet the feed requirement of the following process;

2. After the screening, the materials meeting the feed size is transported into the customized VSI sand maker by conveyor belt, and the unqualified ones are returned to the crusher for another crushing. Here the aggregates from the river stone sand makers are about 0-5mm;

3. Vibrating screener finishes another screening to the materials discharged by the VSI sand making machine. Qualified products are sent into the sand washing machine and then we get the final products. The unqualified particles are sent back to the sand maker to be crushed again till they meet the requirements.

Flow chart of river stone sand making

In the river stone sand production line, two types of mostly used sand crushers are jaw crusher and cone crusher. These two types of crushers have high crushing efficiency to hard materials with high output, which can meet the production needs of the VSI sand making machine.

Besides, the VSI sand making equipment has certain requirements on the fed material size. Together with the jaw crusher and cone crusher, VSI sand maker will increase the efficiency of the whole sand production line.

Jaw Crusher—Primary Crushing Equipment

As the primary crushing equipment, the jaw crusher mainly plays a part in producing a smaller size of aggregates which is suitable for the following process and improves efficiency. It uses the impaction and compression between the moving and fixed jaw to break large river stones.

The maximum feed size of the jaw crusher is between 125-1200mm, which can meet the production requirements of 1-1000TPH. For its remarkable crushing effect on hard materials and low one-time investment, the jaw crusher is the most widely used in the crushing line and sand production plant.

Jaw crusher-the primary crushing equipment

Cone Crusher—Secondary Crushing Equipment

Similar to the jaw crusher, cone crusher is also often used to break hard materials and it completes the last process of sand making machine. Different types of cone crusher machines have the same working principle, which is to crush the raw materials by lamination. This working method produces smaller mechanical wear to the wear parts. Compared to the impact crusher, cone crusher is more suitable for processing hard materials like river stone with higher efficiency.

According to the internal structure and the assistant device, cone crushers are classified into single-cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher, hydraulic cone crusher, etc. Cone crusher uses the eccentric shaft sleeve to drive the movable cone to rotate. And the extrusion and impact between the movable cone and fixed cone realize the crushing. Cone crusher produces cubic products with uniform size, which is incomparable by other crushers.

Cone crusher-the secondary crushing equipment

VSI Sand Making Machine—Customized Sand Maker

VSI sand making machine is a new type of sand machine, also known as an efficient vertical shaft impact crusher. As the core equipment in the river stone sand production line, river stone VSI sand machine can be customized according to customer needs.

The acceleration of the impeller is utilized to eject the material on the material liner. After times of rebinding, the raw materials are impacted, ground and discharged when the particle meets the final requirement.

Compared with the traditional sand machine, river stone VSI sand making machine has the following advantages:

VSI sand making machine

Sand Washing Machine—Sand Cleaning Equipment (Selectable)

The sand washing machine is also called sand cleaning machine. It is used in construction sites, aggregate factory and other fields to clean or grade sand and stone with a large capacity. Based on the working principle and appearance, there are mainly spiral sand washing machine, wheel sand washing machine, etc. The wheel sand washing machine is a new type and mostly used sand cleaning machine recently.

The wheel sand washing machine is used in the pebble sand making plant in Philippine. When it works, the wheel rolls like a windmill under a certain speed. Sand in the washing tank tosses with the rotation and the impurities and foreign bodies with a small specific gravity are taken away by water.

Sand washing machine-sand cleaning machine

Other Equipment—Vibrating Screen/Belt Conveyor/Vibrating Feeder

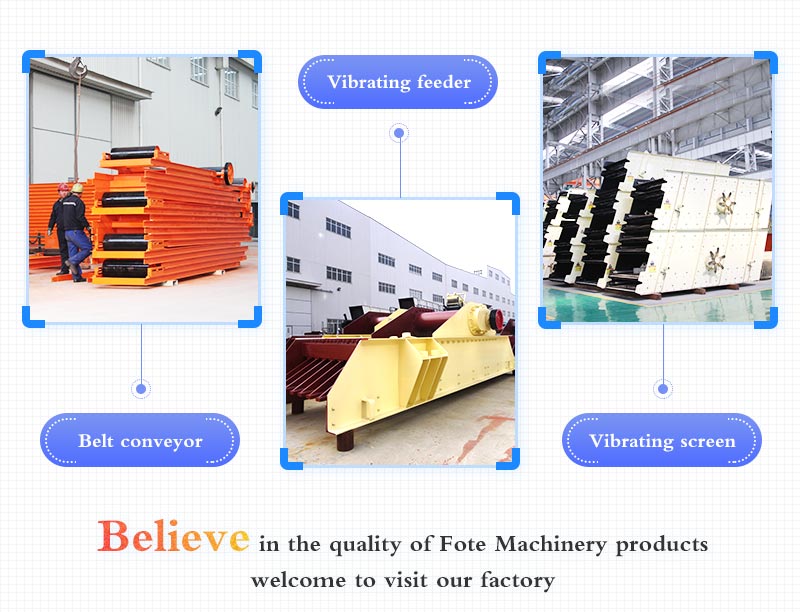

Conveyor belt, vibrating screen and vibrating feeder connect each joint of the pebble sand making plant in the Philippine to improve production efficiency and ensure continuity.

The vibrating screen plays a role of screening and gradation to the materials, eligible materials selected by it are sent by the belt conveyor and fed into the feed port of the next machine by vibrating feeders.

Belt conveyor/vibrating feeder/vibrating screen

Compared with the ore beneficiation plant, the cost of sand making plant is lower. In addition to the one-time investment in machines, the maintenance cost, labor cost, utilities and the site use fee shall be taken into consideration of coat.

Based on the project demand, the machines equipped in river stone sand making plant is different, and so is the cost. Taking the one-time investment of a pebble sand making plant with a capacity of 100-150TPH as an example, tens of thousands to hundreds of thousands of dollars are required.

While from another perspective, with the local infrastructure development, the sand aggregate market will continue to show a period of prosperity. According to the law of the market, when demand exceeds supply, the price of the product will also rise. Investment in the river pebble sand production line will also prove to be a correct choice.

Working site of Fote sand making machine

This river stone sand maker in the Philippine with a capacity of 100-150TPH is just a typical example of sand aggregate production. According to different materials and different site requirements, the sand production process and equipment selection are different.

Usually, pebble sand making machine manufacturers have types of sand makers for sale and it is also free to get the sand making plant solutions. When selecting sand making equipment, investors should consider the scale of sand making machine manufacturers, their product quality, the manufacturers' location and so on. These are important factors affecting the price.

As a professional sand making machine supplier, Fote Machinery is always here to help. If you have any questions, please feel free to consult our engineers online or leave a question on the message board below. You can also send an email to quote@sinoftm.com.

Online Chat

Online Chat