Email (quote@sinoftm.com), we will reply to you within 24 hours

Warranty: 1 Year

Applied Materials: Coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, gypsum, tailings, sludge, kaolin, clay, activated carbon, etc.

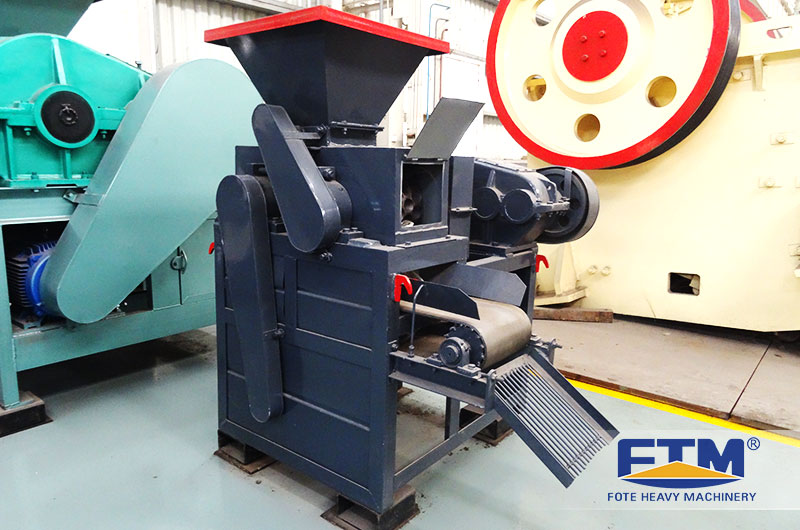

The coal briquetting machine also known as coal dust briquetting machine, can press fly ash or particle coal slime, raw coal and lignite into spherical, oval, flat shape, referred to as briquettes. The finished coal briquetting can be used in power generation, furnace calcination, daily life and other fields.

The coal briquetting machine is mainly used for pressing materials with low moisture content, such as various coal briquettes, mineral powder and refractory materials. Pulverized coal briquetting machine and charred coal briquetting machine are suitable for refractory industry, power plant, metallurgy, chemical industry, energy, transportation, heating and other industries.

Coal briquetting machine can be used to press all kinds of powdery materials like coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, gypsum, tailings, sludge, kaolin, clay, activated carbon, coke and waste residue in refractory, power plant, metallurgy, chemistry, energy, transportation, heating and other industries.

Applications of Coal Briquette Machine

This coal briquetting machine can save energy and protect the environment.The final products are convenient to be transported, thus improve the utilization of the waste materials and have excellent economic and social benefits. In addition, the power consumption of this ball press machine is low.

The performance of the coal briquetting machine is mainly determined by the roller skin of the main engine. This type of coal briquette machine is cast with 65 manganese, and with special heat treatment, its hardness can reach over 58°. The roller skin adopts composite assembly, so that it can be changed when abraded. This briquette machine has a shock absorber which can better protect the equipment from the impact of hard materials. The briquette machine is designed with ball bowl adjustable device to make sure the ball bowls of the two rollers are always in the adjustable range.

Structral Features of Coal Briquetting Machine

Fote Machinery specializes in the production of coal briquetting machine and auxiliary equipment. The raw material can be molded by one press, and the output is high and the hardness is high. It has been used in many domestic power plants, coal washing plants and coal briquette plants and achieved good results. Fote Machinery as a professional coal briquetting machine manufacturer, the production of briquettes with a high ball formation rate, pressure ball hardness is high, not easy to break in the process of handling, which has been recognized by the customer. The coal briquette machine price of our company is favorable and preferential, and we have simple coal briquette press production process, which is available to customers for the on-site testing. If you want to know more, you can pay a visit to coal briquette production sites.

| Model | Roller Diameter (mm) | Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

| Model | Roller Diameter (mm) | Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat