By Fote Machinery Editer

By Fote Machinery Editer

Not only in the gold ore concentrate/separator plant, but also in other ore concentration plant like for iron ore, zinc ore, copper ore, etc.

Production Capacity:10-280TPH

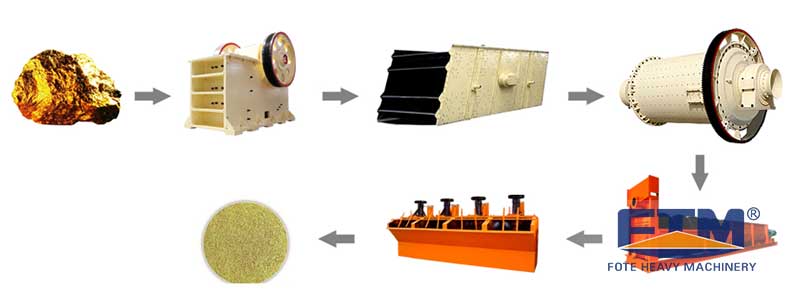

Configuration : Jaw crusher, impact crusher, hammer crusher, flotation machine, classifier, ball mill, concentrator, etc.

The gold ore dressing production line actually refers to the gold ore flotation production line. The gold ore flotation production line mainly uses the flotation reagent to select the specific material. Compared with other mineral processing methods, the gold ore dressing production line has better mineral processing effect and lower energy consumption in production. The ore processing of the gold mine comprises grinding, flotation, classify flotation, rough selection with features like strong scavenging ability, simple operation and good environmental protection performance. Our company can provide the user with a suitable and efficient gold ore dressing production line according to the actual production situation and requirements, so as to ensure higher benefits and lower cost.

Gold ore is a mineral aggregate with enough gold content and industrial utilization. From the value of gold, it is not difficult to find a considerable commercial prospect for the gold ore processing industry. Gold ore can become refined gold and gold products only after mineral processing and then after smelting and extraction to become gold concentrate or gold ore with high grade of gold. Gold is a crystal at room temperature, isometric crystal system, vertical central lattice, and natural good crystal form is very rare, often irregular grain shape, mass, sheet shape, reticulated, dendritic, fiber and sponge aggregates. Pure gold is golden and its color can be changed accordingly when it contains impurities.

The gold mine is initially broken by jaw crusher, and then it can be broken again if necessary. The fine broken gold material already has very fine particle size, then, through the vibrating feeder, the gold ore uniformly and continuously entered ball mill. The material milled by the ball mill enters the flotation machine for flotation, and the flotation agent is added to stir. The flotation is the core of the whole production line. The gold ore material after flotation processing enters the concentrator to concentrate, and then the drying machine carries on the drying operation, then the required gold ore finished product can be obtained.

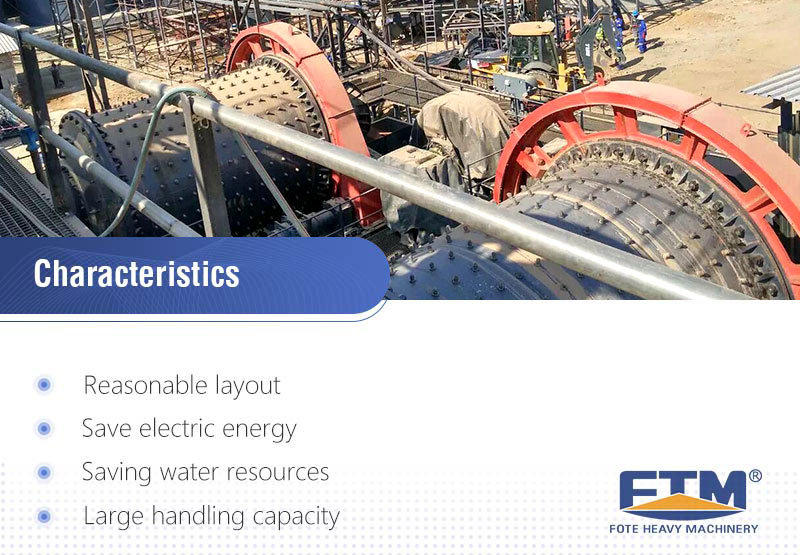

Characteristics of Gold Ore Processing Plant

Online Chat

Online Chat