Preview

Last month, a customer from a medium-scaled wood processing plant found Fote Machinery on Linkedin. He saw a post from our sales and sent an email to quote@sinoftm.com.

We were told that he had had a sawdust dryer for about 5 years but failed to work these days. He'd like to introduce another small-capacity sawdust dryer with a capacity of 5TPH as a replacement.

British Customers Visited Fote Factory

Within 24 hours after receiving his email, our engineer replied him with three customized sawdust dryer solutions based on the details mentioned in his email enclosed with some tips of how to maintain sawdust dryer.

Due to the nature of the material and the working principle of heat exchange, the daily maintenance of sawdust dryer is particularly important.

Fote Sawdust Dryer Customer Site

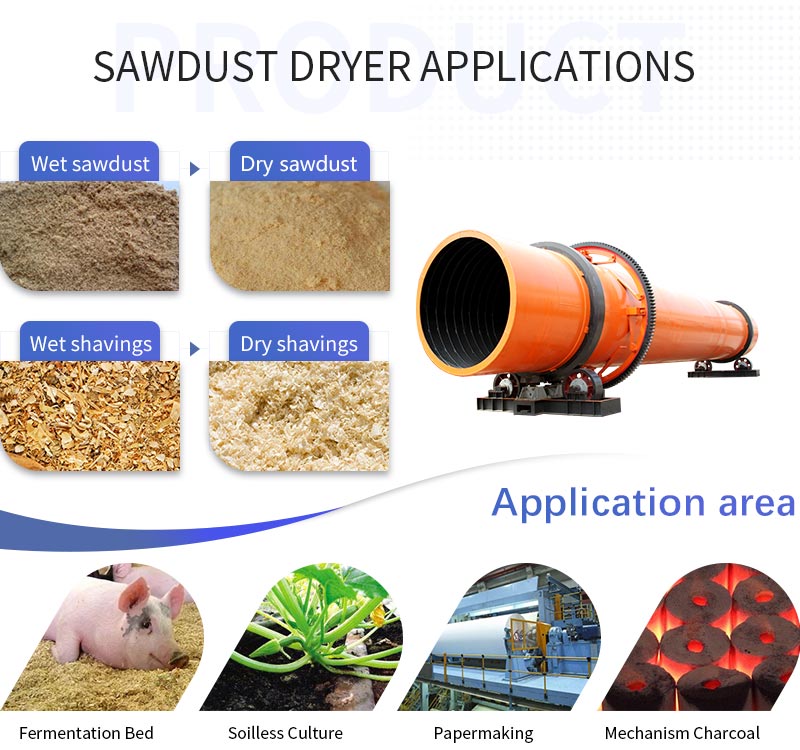

The sawdust dryer is generally a small-sized dryer with low production capacity, which is used for drying the materials such as sawdust and wood chips. It is often used in wood processing, compression plate making, charcoal briquette and so on.

In particular, when the biomass energy source like sawdust is converted into granular fuel, strictly controlling the moisture of the raw materials is primary. Thus, the dryer machine plays an irreplaceable role.

Rotary dryers and air-flow vertical dryers are often used to dewater sawdust. They work in roughly the same way, using the heat exchange between scorching wind and materials to reduce the moisture content. The main working mode is to increase the contact area by cylinder rotating so that it can achieve full drying effect.

Sawdust Dryer Applications

Received the sincere suggestions and felt the profession of Fote engineers, this customer came to our factory and had a site visit last week. At the end of the two-day visit, he decided to introduce a sawdust dryer from Fote.

Fote has established the series of sawdust dryers with introduced international and modern technology from Japan, Germany, America and other countries. From the drying strength of 40% to 100%, Fote offers models of dryer machines for your choice.

For other more details including the latest quotation, please chat online with Fote professional engineers. They are ready to help you with free consultation 24X7.

Fote Machinery Benefits

Online Chat

Online Chat