Email (quote@sinoftm.com), we will reply to you within 24 hours

Precipitation Area: 2.54-7846㎡

Applied Mterial:Slime, waste water, waste slag, tailings in concentrator factory, etc.

Thickener (also known as thickener or agitator) is suitable for concentrate and tailings dehydration treatment during the beneficiation process to increase the slurry concentration from 20-30% to 40-70%. It is of great significance to improve the utilization rate of backwater, the concentration of bottom flow and protect the environment. In fact, the high efficiency concentrator is not a kind of simple sedimentation equipment, but a new type of dehydration equipment combined with the characteristics of mud layer filtration. It is divided into central transmission type, peripheral transmission type, sludge, intermittent type, vertical flow and continuous thickener.

The high efficiency concentrator generally consists of the thickener pool, transmission device, lifting device, feeding device, unloading device and signal safety device. The main feature of this machine is to add a certain amount of flocculant to the pulp to be concentrated, so that the ore particles in the pulp will form flocculation groups and accelerate its settlement rate, so as to improve the concentration efficiency.

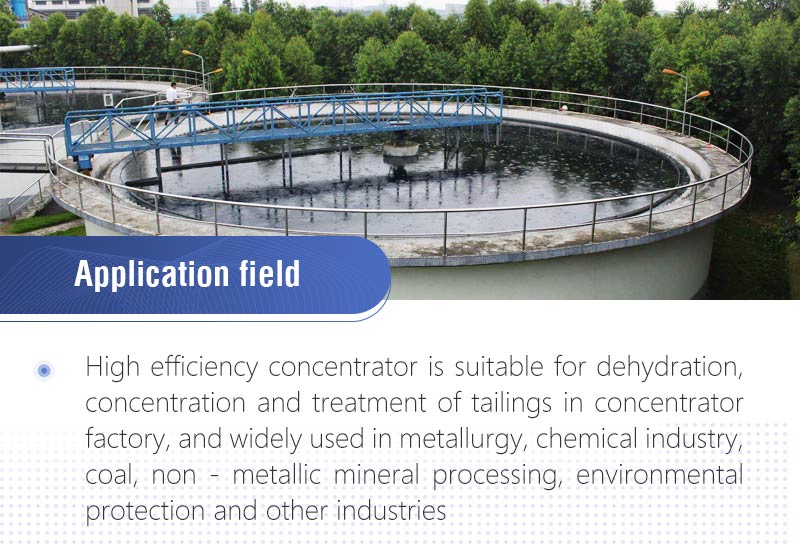

High efficiency concentrator is suitable for dehydration, concentration and treatment of tailings in concentrator factory, and widely used in metallurgy, chemical industry, coal, non-metallic mineral processing, environmental protection and other industries.

The Applications of High Efficiency Concentrator

Increasing the size of solid particles in slurry and the settlement area of high-efficiency concentrator can improve the processing capacity of high-efficiency concentrator. The particle size of settling particles can be increased by adding flocculant to high-efficiency concentrator to make fine particles agglomerate. The inclined plate in the high-efficiency concentrator can increase the settlement area, shorten the settlement distance of particles and improve the concentration efficiency. The test and industrial production shows that under the same processing capacity, the diameter of the high-efficiency thickener is only two-thirds to half of the diameter of the ordinary thickener, and the area is about one-ninth to one-fourth of the ordinary thickener, while the processing capacity per unit area can be increased several times to dozens of times.

| Specification | Concentration pond (m) | Deposit square(m2) | Harrow part | Motor | Processing capacity (t/d) | Total weight(t) | |||||

| Model | Specification | Inner diameter | Depth | Pond degree | Method | Height(m) | Rotation time(min/r) | Driving | Lifting | ||

| NZS-1 | Φ1.8m | 1.8 | 1.8 | 2.54 | Manual | 0.16 | 2 | Y90L-6 1.1KW | ---- | 5.6 | 1.9 |

| NZS-3 | Φ3.6m | 3.6 | 1.8 | 10.2 | Manual | 0.35 | 2.5 | Y90L-6 1.1KW | ---- | 22.4 | 4.3 |

| NZS-6 | Φ6m | 6 | 3 | 28.3 | Manual | 0.2 | 3.7 | Y90S-4 1.1KW | ---- | 62 | 10.7 |

| NZSF-6 | Φ6m | 6 | 3 | 28.3 | Manual | ---- | 3.7 | Y90S-4 1.1KW | ---- | 62 | 5.1 |

| NZ-9 | Φ9m | 9 | 3 | 63.6 | Auto | 0.25 | 4.34 | Y132S-6 3KW | XWD0.8-3 0.8KW | 140 | 8.5 |

| NZS-9 | Φ9m | 9 | 3 | 63.6 | Manual | 0.25 | 4.34 | Y132S-6 3KW | ---- | 140 | 7.5 |

| NZS-12 | Φ12m | 12 | 3.5 | 113 | Manual | 0.25 | 5.28 | JTC752A-44 5.2KW | ---- | 250 | 11.1 |

| NZ-15 | Φ15m | 15 | 4.4 | 176 | Auto | 0.4 | 10.4J | JTC752A-44 5.2KW | Y112M-6 2.2KW | 350 | 26.0 |

| NZ-20 | Φ20m | 20 | 4.4 | 314 | Auto | 0.4 | 10.4 | Y100L1-4 5.2KW | Y112M-6 2.2KW | 960 | 28.9 |

| NZ-30 | Φ30m | 30 | 7.165 | 707 | ---- | 0.61 | 13.7 | Y672A-44 5.2KW | YCJ132-S 1.5KW | ---- | 36.6 |

| NZS-45 | Φ45m | 45 | 4.633 | 1590 | Manual | ---- | 20 | Y672A-44 5.2KW | YCJ160-S 2.2KW | 515 | 54.4 |

| NT-15 | Φ15m | 15 | 3.5 | 177 | ---- | ---- | 8.4 | Y132M2-6 5.5KW | ---- | 390 | 12.6 |

| NQ-18 | Φ18m | 18 | 3.5 | 255 | ---- | ---- | 10 | Y132M2-6 5.5KW | ---- | 560 | 11.6 |

| NQ-24 | Φ24m | 24 | 3.4 | 452 | ---- | ---- | 12.7 | Y160M-6 7.5KW | ---- | 1000 | 26.6 |

| NQ-30 | Φ30m | 30 | 3.6 | 707 | ---- | 16 | Y160M-6 7.5KW | ---- | 1570 | 30.9 | |

| NJ-38 | Φ38m | 38 | 4.9 | 1134 | ---- | ---- | 10-25 | JZT252-4 11KW | Y160M-6 7.5KW | 1600 | 63.3 |

| NT-45 | Φ45m | 45 | 5.05 | 1590 | Auto | ---- | 19.3 | Y160L-6 11KW | ---- | 2400 | 66.8 |

| NTJ-53 | Φ53m | 53 | 5.07 | 2202 | ---- | ---- | 23.18 | Y180L-6 15kw |

---- | 6250 | 89.1 |

| NT-100 | Φ100m | 100 | 5.65 | 7846 | ---- | ---- | 43 | Y180L-6 15KW | ---- | 3030 | 214.9 |

| Specification | Deposit square(m2) | Processing capacity (t/d) | |

| Model | Specification | Pond degree | |

| NZS-1 | Φ1.8m | 2.54 | 5.6 |

| NZS-3 | Φ3.6m | 10.2 | 22.4 |

| NZS-6 | Φ6m | 28.3 | 62 |

| NZSF-6 | Φ6m | 28.3 | 62 |

| NZ-9 | Φ9m | 63.6 | 140 |

| NZS-9 | Φ9m | 63.6 | 140 |

| NZS-12 | Φ12m | 113 | 250 |

| NZ-15 | Φ15m | 176 | 350 |

| NZ-20 | Φ20m | 314 | 960 |

| NZ-30 | Φ30m | 707 | ---- |

| NZS-45 | Φ45m | 1590 | 515 |

| NT-15 | Φ15m | 177 | 390 |

| NQ-18 | Φ18m | 255 | 560 |

| NQ-24 | Φ24m | 452 | 1000 |

| NQ-30 | Φ30m | 707 | 1570 |

| NJ-38 | Φ38m | 1134 | 1600 |

| NT-45 | Φ45m | 1590 | 2400 |

| NTJ-53 | Φ53m | 2202 | 6250 |

| NT-100 | Φ100m | 7846 | 3030 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat