Ball mill is one of the mostly used grinding equipment with high efficiency. It is also one of the most ancient mining machines in the world, while the efficient ball mill was created until the industrial revolution and the invention of steam power.

Ball mill is usually classified based on different aspects:

● Working method: √ dry grinding ball mill; √ wet grinding ball mill

● Discharging methods: √ grate discharge ball mill; √ overflow discharge ball mill

Usually, investors are hesitated to choose ball mills of dry grinding or wet grinding. Here are some tips.

Wet grinding is more used than dry grinding to grind raw materials. Most of the grindable metallic ore and nonmetallic ore can be processed by wet grinding if it doesn't react to water or the reaction influences the finished product quality.

These materials include copper ore, iron ore, gold ore, molybdenum ore, phosphate ore, feldspar ore, fluorite ore, etc.

While other materials like cement, marble and other building aggregates that react to water and will produce other kind of materials only need dry grinding. If the finished product is required to be stored and sold as powder, dry grinding is also the better choice.

Video of Ball Mill Workshop

Sometimes, we also differ ball mills by the materials processed. For example, Fote Machinery has the following kinds of ball mills for sale, gold ore ball mill, black manganese ore ball mill, nickel ore ball mill, tin ore ball mill, copper ore ball mill, garnet ball mill, andalusite ball mill, aluminum gray ball mill, molybdenum ore ball mill, fluorite ball mill and so on.

The working principle of ball mill is simple, while there are several aspects playing part on the particle size adjustment. The followings are the main factors

• The size of grinding media

As the direct contact to the raw material inside the ball mill machine, grinding media is surely the primary matter that affects the discharge size.

The smaller the grinding media, the smaller the discharged particle. The grinding media shall be bigger than the raw materials. Usually, people fill the gap of larger grinding media with smaller ones to achieve a better grinding effect.

• The lining board surface

As another direct contact to raw material, lining board of ball mill also plays an important part in adjusting the discharge particle size.

The discharge size goes with the degree of the lining board flatness. Ball mill with flatter lining board produces finer product.

• The length of the grinding cylinder

If the diameter of the grinding cylinder is the same, the ball mill with longer cylinder has a better grinding efficiency to materials.

A longer grinding cylinder means a longer stay time inside the grinding cylinder. According to customer demand, cylinders of different length grind materials into different sizes.

Different grinding media of ball mill

Ball mill is extensively used in the production of cement, silicate, refractory materials, chemical products, black and nonferrous metal ore dressing, glass ceramics and other industrial products. In recent years, it is also used for artificial sand making in new building materials production.

All kinds of ore and other grindable materials process can be completed by ball mill for dry or wet grinding. Grinding of ball mill meets the high requirements for uniformity pf discharged products.

There are some examples of various ball mills used in different industrial fields.

1. Cement ball mill

Cement ball mill is also shortened as cement mill. It is the main equipment in cement industry with high grinding efficiency, capacity and low energy consumption. Cement mill has superiority in grinding slag cement.

2. Coal ball mill

Coal ball mill is also one kind of ball mill that used to mill raw coal. Usually, to be simplified, we call it coal mill. To improve the burning efficiency, coal need to be ground by coal mill and then used in the pulverized coal-fired boiler. And to prevent casting from burning on or to decrease the surface roughness, high-quality coal dust produced by coal mill is added in the iron casting process.

Applications of Ball Mill

Global Customer Sites of Fote Ball Mill

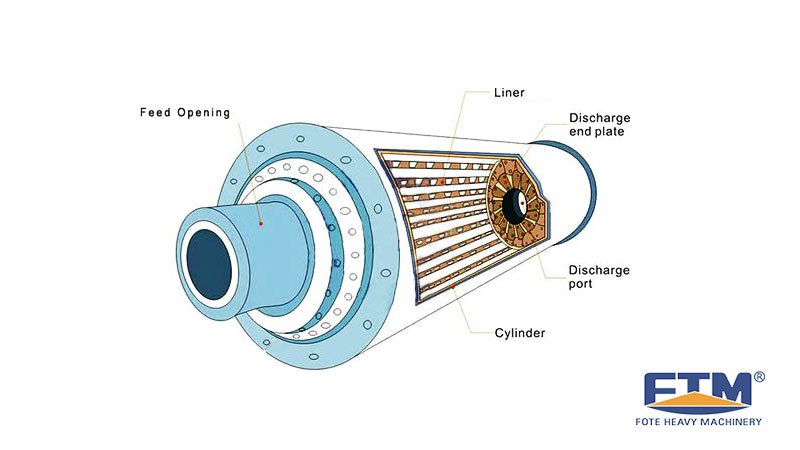

Ball mill is mainly composed of feed port, discharge port, grinding media, grinding cylinder, transmission department, liner, etc.

The hollow shaft is made of cast steel and the inner cylinder is set with a wear-resistant lining plate, which assures a long service life of this machine. Besides, the ball mill is easy to maintain for that the inner lining can be removed and replaced. Gear-hobbing-structured rotary gear ensures a smooth-rolling during the operation.

The Structure of Ball Mill

1. The material uniformly enters the first chamber of the ball mill by the feeding device through the hollow shaft. The chamber has stepped lining or corrugated lining, which is filled with steel balls of different specifications.

2. Then the rotation of the grinding cylinder generates centrifugal force to bring the grinding media to a certain height. After falling, they hit and grind the material.

3. When the material is coarsely ground in the first warehouse, it enters the second warehouse through a single-layer compartment board. This warehouse is provided with a flat lining plate with steel balls inside to further grind the material.

4. The powder is discharged through the discharge raft to complete the grinding operation.

Ball Mill Working Principle

As the ball mill is an ordinary ore processing machine in many fields, here offer one of the most classic examples in industrial plants.

| Fote Ball Mill Customer Site in Mongolia | |

| Customer location | Mongolia |

| Processed material | Copper ore |

| Model | Φ2100x7000 |

| Capacity | 30TPH |

| Discharge size | about 200 mesh |

Customer feedback: By the introduction by my friend, we contacted Fote sales engineer sending the details of our project. The details include capacity needed, the raw material size, the discharge needed. After seeing our working environment, Fote offered a suitable solution and the flow chart. This ball mill grinding line for processing copper ore has worked for us for about two years with all cost recovered and benefits increased.

Dry Type Ball Mill used for Production of Powdery Materials

Fote Machinery has been devoted to mineral processing technology research for more than 40 years. Its ball mill business division is specialized in the production of various types of ball mills. Mature production concept, professional technical research and development team are available for you to supply the high quality ball mill equipment!

As a professional ball mill manufacturer, Fote Machinery provides you with more real and more preferential equipment quotation, and it is the satisfactory choice for you purchasing affordable ball mill. If you want to know the detailed quotation, click chat online for free online consultation or contact us at quote@sinoftm.com

| Model | Shell rotation speed (r/min) | Ball load (t) | Feeding size (mm) | Discharging size (mm) | Capacity (t/h) | Motor power (kw) | Total weight (t) |

| Ф900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | <25 | 0.074-0.4 | As per process conditions | 630 | 149 |

| Ф3600×4500 | 17 | 90 | <25 | 0.074-0.4 | As per process conditions | 850 | 169 |

| Ф3600×6000 | 17 | 110 | <25 | 0.074-0.4 | As per process conditions | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 |

| Model | Feeding size (mm) | Capacity (t/h) |

| Ф900×1800 | <20 | 0.65-2 |

| Ф900×3000 | <20 | 1.1-3.5 |

| Ф1200×2400 | <25 | 1.5-4.8 |

| Ф1200×3000 | <25 | 1.6-5 |

| Ф1200×4500 | <25 | 1.6-5.8 |

| Ф1500×3000 | <25 | 2-5 |

| Ф1500×4500 | <25 | 3-6 |

| Ф1500×5700 | <25 | 3.5-6 |

| Ф1830×3000 | <25 | 4-10 |

| Ф1830×4500 | <25 | 4.5-12 |

| Ф1830×6400 | <25 | 6.5-15 |

| Ф1830×7000 | <25 | 7.5-17 |

| Ф2100×3000 | <25 | 6.5-36 |

| Ф2100×4500 | <25 | 8-43 |

| Ф2100×7000 | <25 | 12-48 |

| Ф2200×4500 | <25 | 9-45 |

| Ф2200×6500 | <25 | 14-26 |

| Ф2200×7000 | <25 | 15-28 |

| Ф2200×7500 | <25 | 15-30 |

| Ф2400×3000 | <25 | 7-50 |

| Ф2400×4500 | <25 | 8.5-60 |

| Ф2700×4000 | <25 | 22-80 |

| Ф2700×4500 | <25 | 26-90 |

| Ф3200×4500 | <25 | As per process conditions |

| Ф3600×4500 | <25 | As per process conditions |

| Ф3600×6000 | <25 | As per process conditions |

| Ф3600×8500 | <25 | 45.8-256 |

| Ф4000×5000 | <25 | 45-208 |

| Ф4000×6000 | <25 | 65-248 |

| Ф4000×6700 | <25 | 75-252 |

| Ф4500×6400 | <25 | 84-306 |

| Ф5030×6400 | <25 | 98-386 |

| Ф5030×8300 | <25 | 118-500 |

| Ф5500×8500 | <25 | 148-615 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat