Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten, tin, tantalum, niobium, etc.

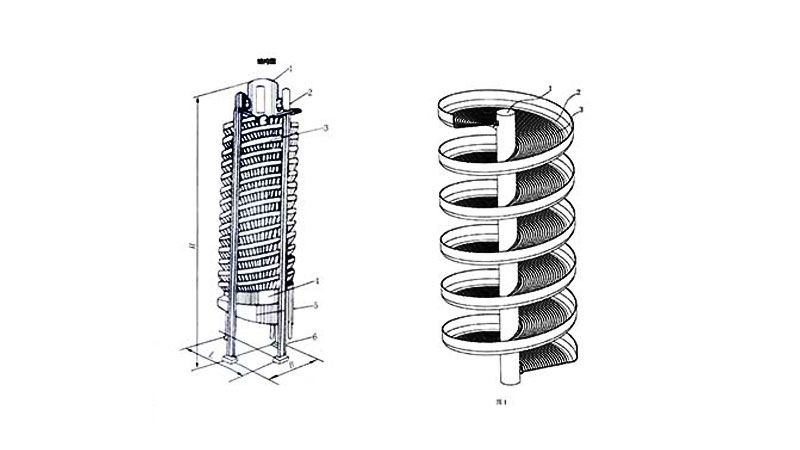

The spiral chute is a new type of domestic equipment developed in 1977, which integrates the advantages of spiral concentrator, shaking table and centrifugal concentrator. Spiral chute is suitable for separation of 0.3- 0.02 mm fine materials. The equipment is stable, easy controllability and has a wide range of permissible concentration. It has the advantages of high enrichment ratio, high recovery rate, small area, low water consumption, simple structure, no power, large handling capacity, simple installation, easy operation, small investment, and quick effect.

Raising the spiral chute, calibrating the vertical line, and fix it in the proper position with iron frame or wood. Sand pump will be sent to the top of the screw two feed mouth, adding appropriate amount of water, adjusting the concentration of mine paddle. Mine pulp flow from high to low, creating a centrifugal force of inertia in the velocity of rotation. The separation of ore and sand can be achieved through the effect of gravity and centrifugal force of the cyclone, and the difference in the specific gravity, particle size and shape of ore and sand. The concentrate flows into the concentrate bucket with the pipe to take out, the tailings flow into the tailings bucket with the pipe to connect to the sand pool, and then with the sand pump to drain away, complete the whole process of dressing.

The Working Principle of spiral chute

Fote Machinery has various types of spiral chutes for sale, such as gravity spiral chute, mineral spiral chute as well as spiral chute for gold, tin, tungsten, etc. The spiral chutes produced by Fote has reliable operation, high efficiency and reasonable price. Customers can choose the appropriate type according to their actual needs. We are always ready to bring more benefits for you!

| Model | Processing capacity (t/h) |

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |

| Model | Processing capacity (t/h) |

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat