Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Tin, tungsten, gold, silver, lead, zinc, antimony, bismuth, iron, manganese, titanium and coal, heavy metal materials, and other metal ore materials, etc.

Shaking table is a gravity separation machine used to separate fine materials, which has been widely used in many industries. It can adopt different working modes such as coarse separation, fine separation and cleaning. It is widely used in the selection of tin, tungsten, gold and silver, lead, zinc, antimony, iron, manganese, ferrotitanium and coal. Our factory has a long history of production of shaker table, and constantly develops and innovates, from straight bed surface shaker to single curved wave bed surface shaker (1970s). The treatment capacity, recovery rate and enrichment ratio of double wave bed surface shaker (1990s) were greatly improved.

Gold shaker table is one of the most important gold separating equipment. Gold generally exists in highly dispersed form in nature, especially alluvial gold. The most widely used in the sorting method of alluvial gold is using the shaking table. Because the gold has high density and certain weight, therefore, adopting the shaking table to separate gold can obtain the final product for one time, which is economical and convenient. In addition, one person can control many shaking tables at the same time, which can save manpower and material resources.

Shaking table has been widely applied in many industries, which can conduct different working modes such as rough separation, fine separation and scavenging. It is suitable for separating gold,silver, tungsten, zinc, iron, manganese, lead, coal and other metal or heavy metal materials. Shaking table is suitable for 2-0.5mm coarse sand, 0.5-0.074mm fine sand and slime in different granularity. When processing tungsten, tin and other metal ore materials, the effective recovery range of shaking table is 2-0.22mm.

The Applications of Shaking Table

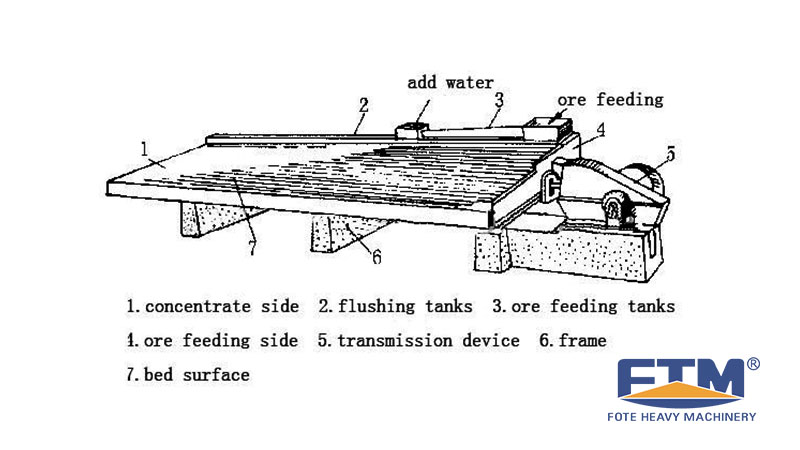

The motor of the shaking table is driven by a belt to cause the pulley to drive the crankshaft of the shaker device to rotate the rocker up and down. As the rocker moves down, the material comes in through the chute on the tilting table, and the shaker flume provides lateral shock water so that it vibrates and flushes at the same time. Minerals with different specific gravity, particle size and density flow out of the concentrate mouth and tailings mouth of the shaker in respectively different directions to form high quality concentrate. Due to the continuous upgrading of mine shaking table, the processing capacity and accuracy of mine shaker has been greatly improved.

The Working structure of Shaking Table

Shaking table working site in Egypt

Shaking table working site in Indonesia

As a powerful ore dressing equipment manufacturer, Fote Machinery has gold shaking table for sale, which has high separating efficiency, low energy consumption, and simple operation. In addition, FTM shaking table price is preferential in the same industry. Welcome to make an inquiry!

| Name | Grit concentrator table | Fine sand concentrator table | Sludge concentrator table | |

| Bed surface Dimensions | Length (mm) | 4450 | 4450 | 4450 |

| Driving part Width (mm) | 1855 | 1855 | 1855 | |

| Concentrate part Width (mm) | 1546 | 1546 | 1546 | |

| Max.feeding size(mm) | 2 | 0.5 | 0.15 | |

| Feeding amount (t/d) | 30-60 | 10-20 | 15-25 | |

| Feeding thickness (%) | 25-30 | 20-25 | 15-25 | |

| Stroke (mm) | 16-22 | 11-16 | 8-16 | |

| Frequency (f) | 45-48 | 48-53 | 50-57 | |

| Bed surface Water quantity (t/d) | 80-150 | 30-60 | 10-17 | |

| Bed surface Horizontal obliquity(°) | 2.5-4.5 | 1.5-3.5 | 1-2 | |

| Bed surface Portrait obliquity(%) | 1.4 | 0.92 | ---- | |

| Table board corner(°) | 32-42 | 40 | 42 | |

| Concentrating area(㎡) | 7.6 | 7.6 | 7.6 | |

| Bed surface Length ratio | 2.6 | 2.6 | 2.6 | |

| Shape of side-bed surface | Rectangle | Zigzag | Triangle | |

| Motor power(kw) | 1.1 | 1.1 | 1.1 | |

| Transmission device | Eccentricity Linkage | |||

| Name | Max.feeding size(mm) | Bed surface Water quantity (t/d) |

| Grit concentrator table | 2 | 80-150 |

| Fine sand concentrator table | 0.5 | 30-60 |

| Sludge concentrator table | 0.15 | 10-17 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat