Email (quote@sinoftm.com), we will reply to you within 24 hours

Warranty Period: 1 Year

Applied Materials: Iron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries.

Slurry refers to the semi solid materials formed by coal and water, which is a kind of product in the coal production process. Due to the varieties and formation natures of materials, their properties difference is very big, which is the same as their usages. Slurry briquetting machine or coal slime briquetting machine is mainly used for pressing slurry into balls and blocks, which can be directly put into the furnace for smelting, so as to increase the added value.

Slurry briquetting machine or coal slime press is mainly used for grouting with high pressure, automatic feeding and other characteristics. The pressed particles have high density and hardness. The series of briquetting machine equipment also includes coal briquetting machine, desulfurization gypsum briquetting machine, ore powder briquetting machine.

The slurry briquette machine is the key equipment of the slurry pressing technology, and its structure directly affects the quality of the size. The main type of press machine is roller press, and it has a pair of parallel shaft, the same diameter and a certain gap of a cylindrical wheel, and there are many hemispherical pits of the same shape and size arranged in regular order. Driven by an electric motor, the twin cylinders rotate at the same speed and in opposite directions. As the material falls into the joint of the twin-cylinder wheels, they begin to withstand pressure and generate volume compression between the two ball pits. As the cylinder wheel continues to rotate, the pit will gradually close and the pressure will increase. Pressure peaks when the distance between the two ball pits is minimized. The cylindrical wheel would then rotate away from each other and the pressure would drop rapidly. When the pressing pressure drops to zero, the precipitated slurry expands and falls off.

Working Principle of Slurry Briquetting Machine

The slurry briquette machinery is widely used in the coal industry, power plants, metallurgy industry, refractory material, chemical industry, energy, transportation, heating, and other industries. For processing coal slimes into briquettes that can be utilized for electricity-generating in power plant, gas making, boiler burning, calcining lime, metal smelting, etc. This coal lime briquetting machine manufactured by Fote Machinery is a great project that is energy-saving and eco-friendly. Using this roller press briquetting machine, your enterprise will obtain enormous economic benefit.

Applications of Slurry Briquetting Machine

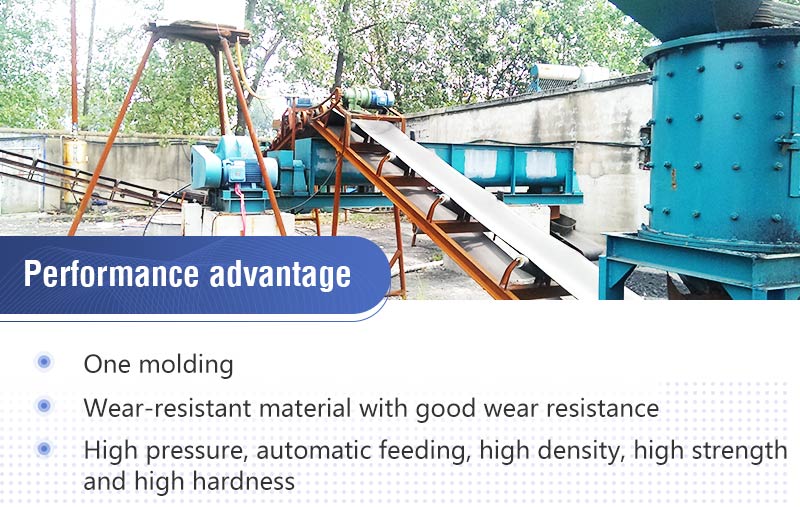

Slurry briquetting machine is aimed at the material which is difficult to mold, so the materials can take shape at one time. It has the features of high pressure, automatic feeding, high extruded sphere density, high strength, and high hardness. It can suppress coal slime into certain shape. The slurry briquetting machine produced by Fote Machinery adopts wear-resisting material, which has good abrasion resistance, so as to improve the service life of the pressing roller. The design principle of the slurry briquette machine is to force the extrusion roller, and the extruded ball has very high density.

Slurry briquetting machine, coal slag briquetting machine and coal breeze briquetting machine are the new flagship products of Fote Machinery, which have reliable quality, perfect service and favorable price. It has extraordinary effect on loose materials. Welcome to consult product details.

| Model | Roller Diameter (mm) | Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

| Model | Roller Diameter (mm) | Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat