Email (quote@sinoftm.com), we will reply to you within 24 hours

Fuel: Coal, mazut, gas, etc.

Application: Widely used for the calcining and production of clay, silt, fly ash, slag, shale, dolomite, kaolin, bauxite, refractory material, cement, limestone, etc.

Ceramsite sand is one kind of sand that mixed by various clay, schist, gangue and other solid waste. It is not a traditional waste but a raw material that can be processed to make thermal insulation materials, sewage water purifiers and so on. Ceramsite sand rotary kiln is such a machine to calcine and produce ceramsite sand with high efficiency. Fote ceramsite sand rotary kiln is equipped with the modern sealing device with advanced technology to prolong kiln liner service life. Besides, it can make use of the waste heat of the secondary inlet air and can realize automatic temperature control, overtemperature alarm.

Fote Rotary Kiln

Ceramsite sand rotary kiln is also called rotary kiln for ceramsite sand, which can also be widely used for the calcining and production of clay, silt, fly ash, slag, shale, dolomite, kaolin, bauxite, refractory material, cement, limestone, titanium powder, ore powder, activated carbon, coke, alumina, magnesium oxide, zinc oxide, special cement, etc. Finished products can be used in the paper making industry, paint production industry, water treatment, and other fields.

FTM ceramsite sand rotary kiln is simply structured and can be stably operated. With advanced technology, this type of rotary kiln is equipped with automatic temperature monitoring device, which can artificially control the temperature change in the kiln. This arrangement results in convenient and flexible production, better calcination effect, strong adaptability to meet the different production needs of different customers.

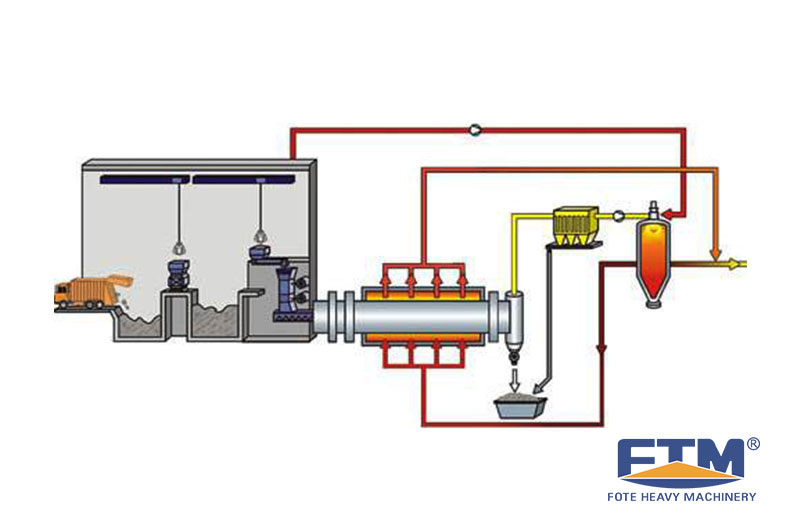

Ceramsite sand rotary kiln is composed of the cylinder, bearing, gear wheel, kiln head, and kiln end. The kiln body has a certain inclination to the horizontal line, which is supported by the supporting wheel and is also equipped with gear wheels. The material will be firstly baked and then enter into the cylinder. In the rotary kiln, the material and hot air flow move in the reverse direction. The semi-finished product after being baked is again raised by the kiln tail chute and then flows into the cylinder body to do the S-shaped rolling motion from top to bottom. During this process, it is gradually dried, heated up, and broken into a glass phase. Then it will enter into the cooling zone and be solidified. Last, the finished product flows out from the lower end of the cooling machine. A complete calcine process is finished.

Working Process of Rotary Kiln

In Nepal, FTM ceramsite sand rotary kiln is used in the ceramsite sand production line with a capacity of 10TPH.

Fote Machinery is one of the professional rotary kiln manufacturers in China with an over 40-year history. We have types of ceramsite sand rotary kiln for sale. Our engineers are skilled and willing to offer you free consultation including the ceramsite sand rotary kiln selection and ceramsite sand rotary kiln price.

| Product Specification (m) |

Kiln dimensions | Motor power (kw) |

Total weight (t) |

note | ||||

| Diameter (m) |

Length (m) |

Obliquity (%) |

Capacity (t/d) |

Rotation speed (r/min) |

||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

----- |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | ----- |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 |

outside disassemble kiln |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 |

outside disassemble kiln |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

outside disassemble klin |

| Φ3.0×60 | 3 | 60 | 3.5 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

disassemble klin |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

kiln with preheater precalcine |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

kiln with prehrater precalcine |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

Generating klin for usimg ofterheat |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

klin with prehrater precalcine |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

klin with prehrater precalcine |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 |

klin with prehrater precalcine |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

klin with prehrater precalcine |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

klin with prehrater precalcine |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

klin with prehrater precalcine |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 |

klin with prehrater precalcine |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 |

klin with prehrater precalcine |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 |

klin with prehrater precalcine |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 |

klin with prehrater precalcine |

| Product Specification (m) |

Capacity (t/d) |

Rotation speed (r/min) |

| Φ2.5×40 | 180 | 0.44-2.44 |

| Φ2.5×50 | 200 | 0.62-1.86 |

| Φ2.5×54 | 280 | 0.48-1.45 |

| Φ2.7×42 | 320 | 0.10-1.52 |

| Φ2.8×44 | 450 | 0.437-2.18 |

| Φ3.0×45 | 500 | 0.5-2.47 |

| Φ3.0×48 | 700 | 0.6-3.48 |

| Φ3.0×60 | 800 | 0.3-2 |

| Φ3.2×50 | 1000 | 0.6-3 |

| Φ3.3×52 | 1300 | 0.266-2.66 |

| Φ3.5×54 | 1500 | 0.55-3.4 |

| Φ3.6×70 | 1800 | 0.25-1.25 |

| Φ4.0×56 | 2300 | 0.41-4.07 |

| Φ4.0×60 | 2500 | 0.396-3.96 |

| Φ4.2×60 | 2750 | 0.41-4.07 |

| Φ4.3×60 | 3200 | 0.396-3.96 |

| Φ4.5×66 | 4000 | 0.41-4.1 |

| Φ4.7×74 | 4500 | 0.35-4 |

| Φ4.8×74 | 5000 | 0.396-3.96 |

| Φ5.0×74 | 6000 | 0.35-4 |

| Φ5.6×87 | 8000 | Max4.23 |

| Φ6.0×95 | 10000 | Max5 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat