Email (quote@sinoftm.com), we will reply to you within 24 hours

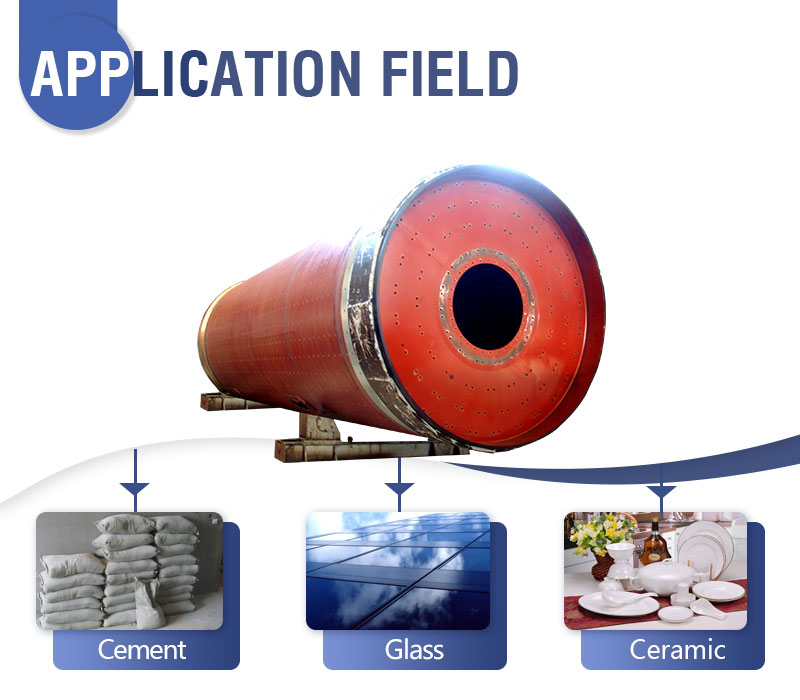

Applied Materials: Cement raw material, Portland products, new building materials, refractories, granite, basalt, iron ore, limestone, calcite, quartz, and diabase, etc. in cement, silicate products, building materials factory, refractory plants, glass, and ceramics factory and other industries.

Raw mill is also called raw material mill, which is the essential equipment in the production process of cement.

It has large application such as raw mill in cement plant, building materials, metallurgy, electric power and chemical industry, which is mainly used for the grinding as well as drying of cement raw materials and other materials. When the raw material is crushed, it will enter the tube mill. With the movement and extrusion of steel balls, it will be ground into fine powder.

The raw mill produced by Fote Machinery has less investment, which is 35~50% lower than traditional equipment with same size. It can satisfy the raw materials supply of 250~2500 t/d cement production line.

Fote Raw Mill

Raw material grinding is commonly used in cement, Portland products, new building materials, refractories, chemical fertilizers, black and non-ferrous metal mineral processing, glass ceramics and other industries. Dry or wet grinding of all kinds of ore and other breakable materials.

It is also suitable for metallurgical, chemical, electric and other industrial and mining enterprises to grind all kinds of ore and other breakable materials. Can be utilized for open flow grinding, but also suitable for circulating circle grinding composed of powder feeder.

Applications of Raw Mill

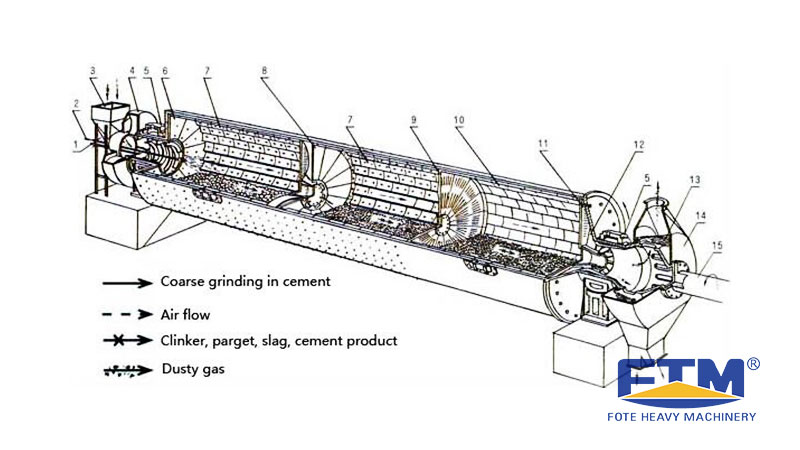

The raw material mill usually adopts the edge transmission mode.

The material to be ground continuously and evenly enters the mill through the feeder and the motor drives the cylinder to rotate through the reducer. The material first spirals into the first milling bin along the hollow shaft. Rotating cylinder brings the material to a certain height.

Under the effect of friction and centrifugal force, it is ground by the steel ball into powder, which is belched out and got separated into qualified particles. While unqualified materials in the circulating grinding system return to the mill to get another ground until the fineness is qualified.

Inside View of Raw Mill

Different specifications of raw mill adopt different transmission mode to meet different requirement, which is laid into edge transmission and central transmission. But generally, there are following advantages.

Sturcture of Raw Mill

>>Common raw material mill

It is suitable for the raw material grinding system of small and medium scale, and is generally used for grinding the ring-flow powder grinding system of the external powder-selecting powder.

>>Air-swept mill

From the outlook of air-swept mill, it is short and coarse. The shaft neck of the inlet and outlet is large, and the gap between the drying bin and the powder grinding bin is large. The tail of the grinding bin is not provided with a discharging deflector, so the ventilation resistance is small that the wind speed can reach above 5m/s.

Therefore, a large amount of hot air improves the drying efficiency.

>>Tail circulate mill

The basic difference between the tail-discharging and lifting circulation mill and the air-sweeping mill is that the grinding material is discharged by a mechanical method at the tail end of the drying bin to the grinding bin, and then is sent to the powder feeder by a hoisting machine, and the coarse material is returned to the mill for recycling and grinding.

>>Middle circulate mill

The middle-discharging and lifting circulate mill is the combination of the air-swept and the tail-discharging and lifting circulate mill, which is equivalent to the secondary-ring-flow grinding system. The head of the mill is provided with a drying bin to provide a good drying effect.

The raw materials are fed at the grinding head and the material from the powder separator is fed into the coarse milling bin and the fine milling bin respectively from the head and the tail. The materials discharged are lifted by the bucket elevator to the powder separator.

When being sorted, most of the materials are returned to the fine milling bin, and the rest of the materials are returned to the coarse milling bin.

FTM Raw Mill

Our Kenya customer found Fote Machinery on the internet and sent us an email about his requirements. These requirements include the material, capacity needed, feed and discharge fineness required.

After several talks with Fote skilled engineer, the customer got the satisfying solution within budget. Here are the details of raw mill processing plant in Kenya.

Processed material: Clinker

Capacity: 50TPD

Feed size: 30mm

Discharge size: 100 mesh

Fote raw mill working site in Kenya

This raw mill is used in the material preparation of cement. The capacity is large enough to meet the requirement and the product has uniform fineness, which helped Fote get good feedback from our customer.

Fote Machinery(FTM) has been specialized in research and development of raw mill for many years. As a professional mining machine manufacturer, FTM not only has high-quality raw mill but also jaw crusher, hammer crusher, sand maker, ball mill, European series grinding machine and other machines for sale.

Our skilled engineers are willing to offer you free consultation including raw mill price, suggestions on machine selection and other details.

| Product specification (m) | Milling form | Transmission form | Gear box | Motor power (kw) | Production capacity (t/h) | Total weight (t) | |

| Model | Speed reduction ratio | ||||||

| Φ1.5×5.7 | Open flow | Brim | ZD40 | 3.55 | 130 | 4.5-6 | 25.8 |

| Φ1.8×6.4 | Open flow | Brim | ZD60 | 4.5 | 210 | 7.5-15 | 43 |

| Φ2.2×6.5 | Circle flow | Brim | ZD70 | 5 | 380 | 14-26 | 60 |

| Φ2.4×7 | Circle flow | Brim | ZD70 | 5 | 475 | 24-28 | 81 |

| Φ2.4×10 | Circle flow | Brim | ZD80-4-LL | 6.44 | 570 | 32-36 | 118 |

| Φ2.6×10 | Circle flow | Brim | JDX710 | 6.3 | 800 | 45-50 | 130 |

| Φ3×9 | Open flow | Brim | JDX800 | 6.3 | 1000 | 55-60 | 158 |

| Φ3.2×9 | Circle flow | Brim | MBY900 | 7.1 | 1250 | 62-65 | 195 |

| Φ3.5×10 | Open flow | Brim | JDX900 | 5.84 | 1250 | 70-75 | 200 |

| Φ3.8×7.5 | Circle flow | Brim | JDX900 | 5.6 | 1600 | 80 | 233 |

| Φ4.6×10+3.5 | Circle flow | Central shaft | JQS3550 | 15.1 | 3550 | 190 | 415 |

| Φ4.6×10.5+3.5 | Circle flow | Central shaft | JQS3550 | 15.1 | 3550 | 210 | 476 |

| Product specification (m) | Milling form | Production capacity (t/h) |

| Φ1.5×5.7 | Open flow | 4.5-6 |

| Φ1.8×6.4 | Open flow | 7.5-15 |

| Φ2.2×6.5 | Circle flow | 14-26 |

| Φ2.4×7 | Circle flow | 24-28 |

| Φ2.4×10 | Circle flow | 32-36 |

| Φ2.6×10 | Circle flow | 45-50 |

| Φ3×9 | Open flow | 55-60 |

| Φ3.2×9 | Circle flow | 62-65 |

| Φ3.5×10 | Open flow | 70-75 |

| Φ3.8×7.5 | Circle flow | 80 |

| Φ4.6×10+3.5 | Circle flow | 190 |

| Φ4.6×10.5+3.5 | Circle flow | 210 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat