Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Limestone, dolomite, kaolin, bauxite, refractory charge, cement clinker, titanium powder, alumina ore, etc. in metallurgy, refractory material, mining, chemical plant, etc.

Limestone is a natural rock with the main component of calcium carbonate whose Mohs hardness is 3. It can be directly processed into stone materials and used for industrial products such as in building materials, highways, metallurgy, chemical industry and so on. Besides, lime can be fired into quicklime, and used in the industries of water quality treatment, asphalt improvement, desulfurization, building materials, medicine and the like.

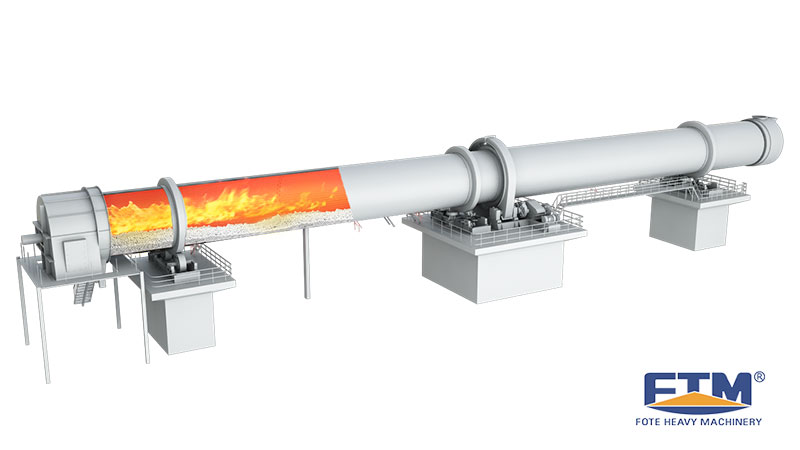

Lime kiln is also named as limestone rotary kiln and active lime kiln, which is the main equipment for calcining active lime into carbon dioxide and calcium oxide, the latter of which is what we call quick lime. With advantages such as reasonable structure, good sealing property, less thermal radiation loss, and high level of automation, FTM has models of customized lime kiln for sale.

The main structure of limestone rotary kiln includes the supporting device, kiln head, kiln tail sealing device, rotary cylinder, coal burner and so on. The kiln body is located on the roller and has a horizontal inclination of about 3 °. The supporting wheel device is used to support the whole kiln body, and the retaining wheel device is used to control the movement of the kiln body up and down.

When lime kiln works, crushed lime in the material bin is screened and lifted to the upper bin of the pre-heating device. Then it is scattered in each room of the pre-heating device and gets heat exchange with smoke. Herein the lime is 30% decomposition. Fully preheated lime gets into the calcination through the tail chute. Lime goes slowly through the pre-heating zone, calcination zone and cooler, in which process, it is calcinated into CaO and CO2. Finished lime is cooled below 100℃ and exhausted out to the store by bucket elevator and belt conveyor.

In Philippine, FTM rotary kiln is used in the limestone line with a production capacity of 100TPH.

As one of the powerful limestone kiln manufacturers in China, Fote Machinery has a number of the high-quality lime kilns for sale. Skilled FTM engineers are here to offer you professional and free consultation including solution on kiln selection, lime kiln price, and the flow chart, etc.

| Design capacity (t/d) |

150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

|

| Preheater | round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre-heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

Vertical Polygon preheater |

Vertical Polygon preheater |

Vertical Polygon preheater |

|

| Rotary kiln |

Specification (m) |

Φ2.5 × 40 |

Φ2.8 × 42 |

Φ3 × 46 |

Φ3.2 × 50 |

Φ3.5 × 54 |

Φ3.6 × 56 |

Φ3.8 × 58 |

Φ4×60 Φ4.2×50 |

Φ4.3 × 58 |

Φ4.3 × 64 |

Φ4.8 × 68 |

| Effective volume (m³) |

142 | 190 | 235 | 292 | 390 | 430 | 505 | 575/548 | 670 | 738 | 1005 | |

| Burning temperature (°C) |

1350/ 1250 |

1350/ 1250 |

1350/ 1250 |

1350/ 1250 |

1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| Cooler | Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

|

| Fuel | Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

|

| Heat rate ( KJ/KgC3O

) |

5300/ 5000 |

5300/ 5000 |

5300/ 5000 |

5300/ 5000 |

5225 | 5225 | 5100 | 5100 | 4810 | 4810 | 4810 | |

| Design capacity (t/d) | Preheater | Heat rate ( KJ/KgC3O

) |

| 150 | round vertical pre- heater or polygonal vertical pre- heater | 5300/ 5000 |

| 200 | round vertical pre- heater or polygonal vertical pre- heater | 5300/ 5000 |

| 250 | round vertical pre- heater or polygonal vertical pre- heater | 5300/ 5000 |

| 300 | round vertical pre- heater or polygonal vertical pre- heater | 5300/ 5000 |

| 350 | round vertical pre- heater or polygonal vertical pre- heater | 5225 |

| 400 | round vertical pre- heater or polygonal vertical pre- heater | 5225 |

| 500 | round vertical pre- heater or polygonal vertical pre- heater | 5100 |

| 600 | round vertical pre- heater or polygonal vertical pre- heater | 5100 |

| 750 | Vertical Polygon preheater | 4810 |

| 800 | Vertical Polygon preheater | 4810 |

| 1000 | Vertical Polygon preheater | 4810 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat