Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Dolomite, kaolin, bauxite, refractory charge, cement, limestone, titanium powder, bauxite ore, activated carbon, coke, slag, alumina, magnesium oxide, zinc oxide, blast furnace slag, coal, metal powder, phosphate, ammonium sulfate, etc.

Cooling machine also can be called cooler or rotary drum cooler that is often used to cool the clinker of the 500~2000t/d production line. It is a kind of machine to cool material for further process. Industrial cooling machine can be laid into various types including single-cylinder cooling machine, double-cylinder cooling machine, condensing type cooling machine, clinker cooling machine, etc. The single-cylinder cooling machine can be used for cooling the raw material with a certain temperature after being dried. Then the material can get further processed. It plays a very important role in the rotary kiln system, cooling the clinker after high-temperature processing, and is usually used for cooling the clay, the magnesite and the sintered dolomite.

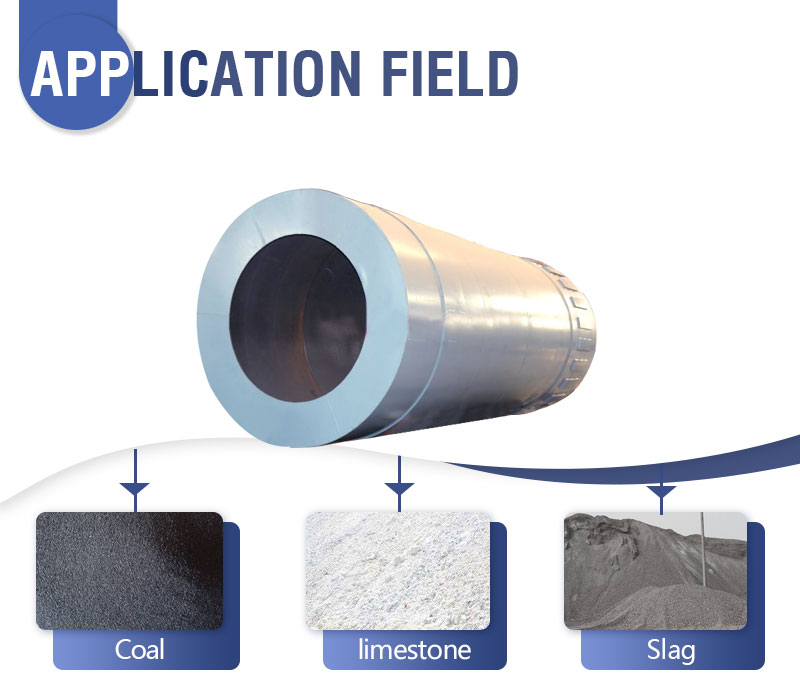

The cooling machine is mainly used for cooling clinker, slag, limestone, coal and clay in the building materials industry, metallurgy industry, chemical industry, cement industry, etc. The single-cylinder cooling machine is one of the important equipment in the rotary kiln system, which is to cool the clinker (1000-1300℃) from the rotary kiln to below 200℃ and to improve the quality of the clinker.

Application of Cooling Machine

The high-temperature clinker enters the cooler through the feed device, and the cooler rotates to drive the material to do the full heat exchange with the air. At the same time, as the kiln body rotates according to the designed slope and rotating speed, the material also rolls forward periodically in the kiln. Thus, the raw material is transported from the feed end to the discharge end, and it is ensured that the material will be cooled below 200℃ when the material passes through the rotary kiln.

Working Principle of Cooling Machine

As the important part of the cooling machine in many industries like cement plant, it is necessary to select a suitable cooling machine from so many models. There are some factors that can be taken into consideration. First of all, the adaptability to the materials. That means before the selection of a cooling machine, it shall be considered that whether the material achieves the cooling degree and uniformity of the cooling products. Second, the effect from the cooling machine to the quality of products. Some products are required to maintain a crystal shape; some products cannot be deformed or cracked. Last but not the least, thermal efficiency. That the thermal efficiency is high or low is the is the main technical and economic indexes of cooling machine.

| Spec./m (Dia×Length) |

Capacity (t/h) |

Installation Obliquity (%) |

Main Reducer |

Main Motor (kw) |

Weight (t) |

| Φ1.5×15 | 2~3 | 3~5 | ZQ500 | 15 | 28 |

| Φ1.5×20 | 3~4 | 3~5 | ZQ500 | 15 | 35 |

| Φ1.8×18 | 4~6 | 3~5 | ZQ500 | 18.5 | 47 |

| Φ2.0×22 | 7~8.5 | 3~5 | ZQ500 | 22 | 61 |

| Φ2.2×18 | 7~8.5 | 3~5 | ZQ500 | 22 | 64 |

| Φ2.2×22 | 8~10 | 3~5 | ZQ650 | 30 | 73 |

| Φ2.4×24 | 12~15 | 3~5 | ZS125 | 45 | 98 |

| Φ2.5×25 | 15~20 | 3~5 | ZS125 | 55 | 110 |

| Φ2.8×28 | 16~22 | 3~5 | ZL100 | 55 | 130 |

| Φ3.0×30 | 20~25 | 3~5 | ZL115 | 75 | 169 |

| Φ3.2×36 | 28~32 | 3~5 | ZL115 | 90 | 200 |

| Φ3.3×40 | 32~36 | 3~5 | ZI130 | 132 | 237 |

| Φ3.6×36 | 35~38 | 3~5 | ZSY450-28 | 185 | 318 |

| Φ4.0×36 | 50~60 | 3~5 | ZSY450-25 | 220 | 348 |

| Φ4.0×45 | 60~70 | 3~5 | ZSY450-25 | 250 | 414 |

| Φ4.5×50 | 70~75 | 3~5 | ZSY500-25 | 315 | 576 |

| Spec./m (Dia×Length) |

Capacity (t/h) |

Installation Obliquity (%) |

Main Reducer |

| Φ1.5×15 | 2~3 | 3~5 | ZQ500 |

| Φ1.5×20 | 3~4 | 3~5 | ZQ500 |

| Φ1.8×18 | 4~6 | 3~5 | ZQ500 |

| Φ2.0×22 | 7~8.5 | 3~5 | ZQ500 |

| Φ2.2×18 | 7~8.5 | 3~5 | ZQ500 |

| Φ2.2×22 | 8~10 | 3~5 | ZQ650 |

| Φ2.4×24 | 12~15 | 3~5 | ZS125 |

| Φ2.5×25 | 15~20 | 3~5 | ZS125 |

| Φ2.8×28 | 16~22 | 3~5 | ZL100 |

| Φ3.0×30 | 20~25 | 3~5 | ZL115 |

| Φ3.2×36 | 28~32 | 3~5 | ZL115 |

| Φ3.3×40 | 32~36 | 3~5 | ZI130 |

| Φ3.6×36 | 35~38 | 3~5 | ZSY450-28 |

| Φ4.0×36 | 50~60 | 3~5 | ZSY450-25 |

| Φ4.0×45 | 60~70 | 3~5 | ZSY450-25 |

| Φ4.5×50 | 70~75 | 3~5 | ZSY450-25 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat