The rotary kiln was created in cement production. Dating back to 1824, an English cement worker developed the first interval operated vertical kiln. About 30 years later, another English people R&D the rotary kiln. From then on, the cement industry gets rapid development and meanwhile, the rotary kiln gets generation development.

As a kind of commonly used calcining equipment, rotary kiln is widely used in construction, building materials, metallurgy, chemical industry and environmental protection industry. In addition to the calcination of clay, limestone, slag, iron, aluminum, copper, zinc, iron ore, concentrate and intermediate materials, it also has thermal reaction, heat exchange, degradation and utilization of waste and other functions.

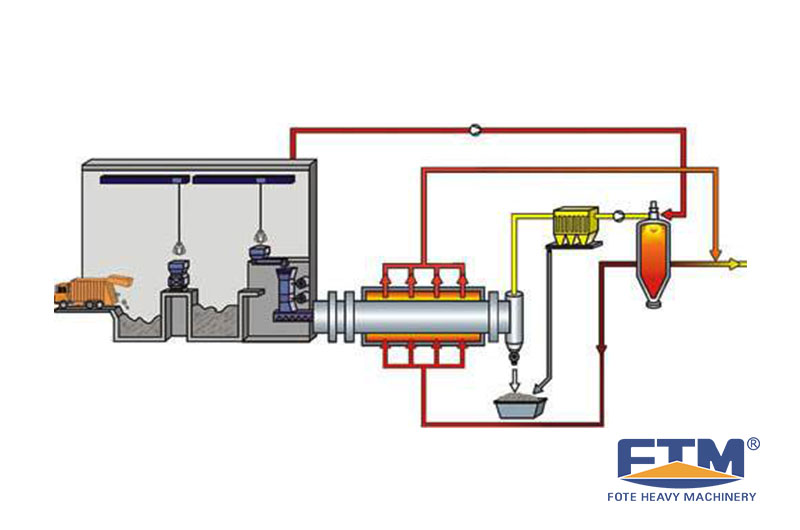

Fote Rotary Kiln Flow Chart

>>Building Materials Industry

In addition to the calcination of clinker, the kiln can also be used for the drying of limestone, slag, and clay, etc. In refractory material production, the rotary kiln is used to calcinate and keep a stable size of the raw material and improve the strength.

>>Ore Dressing Industry

In the ore processing, rotary kiln can be used to magnetizing roast the deletion iron to improve the magnetism, which is better for the magnetic concentration.

>>Metallurgical Industry

It is usually used for the sintering of ore, concentrates, intermediate materials and for the smelting of iron, aluminum, copper, zinc, tin, nickel, tungsten, chromium, file, and other non-ferrous and ferrous metal.

>>Environmental Protection Industry

The cement kiln is used in hazardous waste and other waste burning. After the kilning process, waste can be harmless and be used as a resource.

>>Chemical Industry

Rotary kiln for the production of soda, calcined phosphate fertilizer, barium sulfide, etc. The mode of phosphoric acid production by rotary kiln can date back to the 1960s. After near half a century, this process is developed with the advantages of low energy consumption and no use of sulphuric acid, etc.

Rotary Kiln Applied in Different Industries

Rotary kiln is a cylinder set at a certain angle. When a rotary kiln works, the cylinder rotates to make the materials inside get fully mixed and contacted. Coal injection combustion at kiln head produces a lot of heat that is transmitted to the materials by the fire radiation, scorching air exchange and the transmission of the body. Materials steps forwards under the effect of gravity and the rotation of the cylinder.

It mainly consists of the body, a driving device, a supporting device, blocking wheel, kiln head sealing device, kiln tail sealing device and kiln hood.

Rotary Kiln Process

1. According to the exterior, it can be divided into variable-diameter rotary kiln and path rotary kiln;

2. According to the usage, it can be divided into the cement rotary kiln, magnesium metal rotary kiln, ceramsite sand rotary kiln, kaolin rotary kiln, lime rotary kiln, etc.

3. According to the fuel, it can be divided into gas rotary kiln, coal rotary kiln and mixed-fuel rotary kiln.

Early in last year, a customer who runs a medium clinker production plant emailed at quote@sinoftm.com leaving a message for rotary kiln. He needed a kiln to process limestone with a capacity of about 50TPH. Fote engineer gave him a reply as soon as possible and provided him with two alternative solutions based on his requirements.

This customer from South Africa paid a visit to Fote factory and concluded the contract. After about two-week delivery, he received the goods and got a professional site installation guidance from Fote engineer. Recently, our engineer has gained a good feedback from him.

Fote Rotary Kiln at Customer Site

With an about 40-year experience, Fote Machinery has developed itself to a higher stage. More than 2300 employees including over 360 skilled engineers can offer you customized solutions with the by-heart design and production of various rotary kiln for sale, which has passed the ISO9001 quality certification.

The rotary kiln price of our company is favorable among rotary kiln manufacturers. Besides, we have introduced advanced international technology from German, Japan, America, etc. as our support. For more details about rotary kiln, welcome to chat online with our experienced engineers or leave a message.

| Product Specification (m) | Kiln dimensions | Motor power (kw) | Total weight (t) | note | ||||

| Diameter (m) | Length (m) | Obliquity (%) | Capacity (t/d) | Rotation speed (r/min) | ||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 | ----- |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | ----- |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 | outside disassemble kiln |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 | outside disassemble kiln |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | outside disassemble klin |

| Φ3.0×60 | 3 | 60 | 3.5 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | disassemble klin |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | kiln with preheater precalcine |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | kiln with prehrater precalcine |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | Generating klin for usimg ofterheat |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | klin with prehrater precalcine |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | klin with prehrater precalcine |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 | klin with prehrater precalcine |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | klin with prehrater precalcine |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | klin with prehrater precalcine |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | klin with prehrater precalcine |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | klin with prehrater precalcine |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | klin with prehrater precalcine |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | klin with prehrater precalcine |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | klin with prehrater precalcine |

| Product Specification (m) | Capacity (t/d) | Rotation speed (r/min) |

| Φ2.5×40 | 180 | 0.44-2.44 |

| Φ2.5×50 | 200 | 0.62-1.86 |

| Φ2.5×54 | 280 | 0.48-1.45 |

| Φ2.7×42 | 320 | 0.10-1.52 |

| Φ2.8×44 | 450 | 0.437-2.18 |

| Φ3.0×45 | 500 | 0.5-2.47 |

| Φ3.0×48 | 700 | 0.6-3.48 |

| Φ3.0×60 | 800 | 0.3-2 |

| Φ3.2×50 | 1000 | 0.6-3 |

| Φ3.3×52 | 1300 | 0.266-2.66 |

| Φ3.5×54 | 1500 | 0.55-3.4 |

| Φ3.6×70 | 1800 | 0.25-1.25 |

| Φ4.0×56 | 2300 | 0.41-4.07 |

| Φ4.0×60 | 2500 | 0.396-3.96 |

| Φ4.2×60 | 2750 | 0.41-4.07 |

| Φ4.3×60 | 3200 | 0.396-3.96 |

| Φ4.5×66 | 4000 | 0.41-4.1 |

| Φ4.7×74 | 4500 | 0.35-4 |

| Φ4.8×74 | 5000 | 0.396-3.96 |

| Φ5.0×74 | 6000 | 0.35-4 |

| Φ5.6×87 | 8000 | Max4.23 |

| Φ6.0×95 | 10000 | Max5 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat