Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials:Iron ore, copper ore, gold ore, river gravel, limestone, granite, basalt, diabase, andesite, etc.

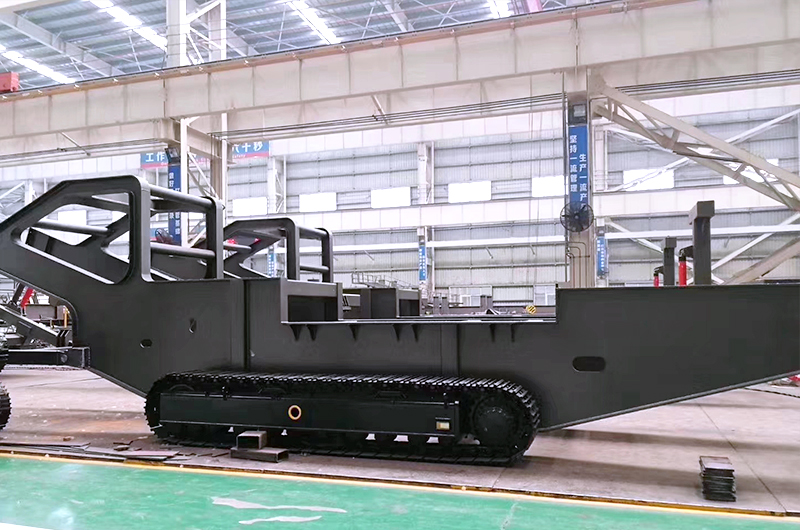

Tracked impact crusher, hereinafter referred to as tracked mobile impact crusher. It is a gravel equipment after upgrading and renovating traditional impact crusher with many advantages such as high crushing efficiency and complete functions, and it can meet the requirements of medium and fine materials crushing and screening in a wide range. Known as the "artifact" of secondary crushing, it can realize independent operation and form flexible configuration of joint operation. The tracked impact crusher adopts integrated operation, which can crush materials on site, eliminating the intermediate link from the site to the crushing field, and greatly reducing the transportation cost of materials. Tracked impact crusher can also be called tracked mounted impact crusher and tracked mobile impact crusher.

>>High performance and efficiency impact crusher.

>>Integrated vehicle mounting of feeder, belt conveyor, and vibrating screen.

>>Equipped with steering shaft of traction for convenient transportation and thoroughly site work.

>>Vehicle-mounted motor and control cabinet.

The tracked impact crusher is suitable for medium hardness or soft materials, such as limestone, river stone, granite, basalt, diabase, ore tailings, construction waste, etc. Tracked impact crusher is widely used in places such as gravel yard, construction waste treatment plant and concrete mixing plant, which can break more than 200 kinds of materials.

Applications of Tracked Impact Crusher

Fote tracked impact crusher is a kind of high efficiency crushing equipment, which has self-driven mode, advanced technology, complete functions and models. Tracked impact crusher has large crushing ratio and the optimized design, which can meet the crushing technology needed by crushing equipment, which has high productivity and uniform product granularity. Fote tracked impact crusher for sale is economical, factory direct sale, saving middlemen marketing costs. Welcome to our factory for the visit.

| Model | WT110 | WT110S | WT1213 | WT1213S | WT1315 | |

| Dimensions of Transmission Devices | Length | 14000mm | 16000mm | 15500mm | 19000mm | 17000mm |

| Width | 3000mm | 3200mm | 3200mm | 3600mm | 3200mm | |

| Height | 3600mm | 3600mm | 3800mm | 3800mm | 3800mm | |

| Weight | 40t | 45t | 53t | 60t | 65t | |

| Feeder | Hopper Volume | 3m³ | 3m³ | 5m³ | 5m³ | 5m³ |

| Loading Height | 3900mm | 4000mm | 3900mm | 4100mm | 4000mm | |

| Primary Screen | Power | 5.2kw | 5.2kw | 6.12kw | 6.12kw | 6.12kw |

| Sieve Dimensions | 1040×924mm | 1040×924mm | 1140×924mm | 1140×924mm | 1240×930mm | |

| Crusher | Model | CI1110M | CI1110M | CI1213M | CI1213M | CI1315M |

| Inlet Dimensions | 1020×860mm | 1020×860mm | 1320×900mm | 1320×900mm | 1540×900mm | |

| Max.Feeding Size | 400mm | 400mm | 500mm | 500mm | 600mm | |

| The Feeder at the Bottom | Hopper Volume | 0.8m³ | 0.8m³ | 1m³ | 1m³ | 1.5m³ |

| Power | 5.2kw | 5.2kw | 5.2kw | 5.2kw | 6.12kw | |

| Unearthed Belt Conveyors | Dimensions (Width×Length) | 650×3500mm | 650×3500mm | 650×3500mm | 650×3500mm | 650×3500mm |

| Dumping Height | 2200mm | 2200mm | 2200mm | 2200mm | 2400mm | |

| Main Belt Conveyor | Dimensions (Width×Length) | 1000×8500mm | 1000×8500mm | 1000×9900mm | 1000×9900mm | 1200×11000mm |

| Dumping Height | 3300mm | 3300mm | 3500mm | 3500mm | 3800mm | |

| Secondary Screen | Power | ○ | 6.12kw | ○ | 6.12kw | ○ |

| Sieve Dimensions | ○ | 1500×3600 | ○ | 1500×4200 | ○ | |

| Belt Conveyors at the Bottom | Dimensions (Width×Length) | ○ | 1000×5800mm | ○ | 1000×6200mm | ○ |

| Dumping Height | ○ | 2900mm | ○ | 3000mm | ○ | |

| Transferring Belt Conveyor | Dimensions (Width×Length) | ○ | 650×2500mm | ○ | 650×2800mm | ○ |

| Dumping Height | ○ | 1400mm | ○ | 1400mm | ○ | |

| Belt Conveyors for Discharging Material | Dimensions (Width×Length) | ○ | 500×8000mm | ○ | 500×9200mm | ○ |

| Dumping Height | ○ | 4200mm | ○ | 4500mm | ○ | |

| Iron Remover | Model | RCYQ-10 | RCYQ-10 | RCYQ-10 | RCYQ-10 | RCYQ-10 |

| Diesel Engine | Power | 96kw | 106kw | 106kw | 132kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | Carter Perkins | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 253kw | 274kw | 304kw | 324.4kw | 366kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | |

Model WT110 and WT110S

| Model | WT110 | WT110S | |

| Dimensions of Transmission Devices | Length | 14000mm | 17000mm |

| Width | 3000mm | 3200mm | |

| Height | 3600mm | 3600mm | |

| Weight | 40t | 45t | |

| Feeder | Hopper Volume | 3m³ | 5m³ |

| Loading Height | 3900mm | 4000mm | |

| Primary Screen | Power | 5.2kw | 6.12kw |

| Sieve Dimensions | 1040×924mm | 1040×924mm | |

| Crusher | Model | CI1110M | CI1315M |

| Inlet Dimensions | 1020×860mm | 1020×860mm | |

| Max.Feeding Size | 400mm | 400mm | |

| The Feeder at the Bottom | Hopper Volume | 0.8m³ | 1.5m³ |

| Power | 5.2kw | 5.2kw | |

| Unearthed Belt Conveyors | Dimensions (Width×Length) | 650×3500mm | 650×3500mm |

| Dumping Height | 2200mm | 2200mm | |

| Main Belt Conveyor | Dimensions (Width×Length) | 1000×8500mm | 1200×11000mm |

| Dumping Height | 3300mm | 3300mm | |

| Secondary Screen | Power | ○ | ○ |

| Sieve Dimensions | ○ | 1500×3600 | |

| Belt Conveyors at the Bottom | Dimensions (Width×Length) | ○ | ○ |

| Dumping Height | ○ | 2900mm | |

| Transferring Belt Conveyor | Dimensions (Width×Length) | ○ | ○ |

| Dumping Height | ○ | 1400mm | |

| Belt Conveyors for Discharging Material | Dimensions (Width×Length) | ○ | ○ |

| Dumping Height | ○ | 4200mm | |

| Iron Remover | Model | RCYQ-10 | RCYQ-10 |

| Diesel Engine | Power | 96kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 253kw | 366kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | |

Model WT1213 and WT1213S

| Model | WT1213 | WT1213S | |

| Dimensions of Transmission Devices | Length | 15500mm | 17000mm |

| Width | 3200mm | 3600mm | |

| Height | 3800mm | 3800mm | |

| Weight | 53t | 60t | |

| Feeder | Hopper Volume | 5m³ | 5m³ |

| Loading Height | 3900mm | 4100mm | |

| Primary Screen | Power | 6.12kw | 6.12kw |

| Sieve Dimensions | 1140×924mm | 1140×924mm | |

| Crusher | Model | CI1213M | CI1315M |

| Inlet Dimensions | 1320×900mm | 1320×900mm | |

| Max.Feeding Size | 500mm | 500mm | |

| The Feeder at the Bottom | Hopper Volume | 1m³ | 1.5m³ |

| Power | 5.2kw | 5.2kw | |

| Unearthed Belt Conveyors | Dimensions (Width×Length) | 650×3500mm | 650×3500mm |

| Dumping Height | 2200mm | 2200mm | |

| Main Belt Conveyor | Dimensions (Width×Length) | 1000×9900mm | 1200×11000mm |

| Dumping Height | 3500mm | 3500mm | |

| Secondary Screen | Power | ○ | ○ |

| Sieve Dimensions | ○ | 1500×4200 | |

| Belt Conveyors at the Bottom | Dimensions (Width×Length) | ○ | ○ |

| Dumping Height | ○ | 3000mm | |

| Transferring Belt Conveyor | Dimensions (Width×Length) | ○ | ○ |

| Dumping Height | ○ | 1400mm | |

| Belt Conveyors for Discharging Material | Dimensions (Width×Length) | ○ | ○ |

| Dumping Height | ○ | 4500mm | |

| Iron Remover | Model | RCYQ-10 | RCYQ-10 |

| Diesel Engine | Power | 106kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 304kw | 366kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | |

Model WT1315

| Model | WT1315 | |

| Dimensions of Transmission Devices | Length | 17000mm |

| Width | 3200mm | |

| Height | 3800mm | |

| Weight | 65t | |

| Feeder | Hopper Volume | 5m³ |

| Loading Height | 4000mm | |

| Primary Screen | Power | 6.12kw |

| Sieve Dimensions | 1240×930mm | |

| Crusher | Model | CI1315M |

| Inlet Dimensions | 1540×900mm | |

| Max.Feeding Size | 600mm | |

| The Feeder at the Bottom | Hopper Volume | 1.5m³ |

| Power | 6.12kw | |

| Unearthed Belt Conveyors | Dimensions (Width×Length) | 650×3500mm |

| Dumping Height | 2400mm | |

| Main Belt Conveyor | Dimensions (Width×Length) | 1200×11000mm |

| Dumping Height | 3800mm | |

| Secondary Screen | Power | ○ |

| Sieve Dimensions | ○ | |

| Belt Conveyors at the Bottom | Dimensions (Width×Length) | ○ |

| Dumping Height | ○ | |

| Transferring Belt Conveyor | Dimensions (Width×Length) | ○ |

| Dumping Height | ○ | |

| Belt Conveyors for Discharging Material | Dimensions (Width×Length) | ○ |

| Dumping Height | ○ | |

| Iron Remover | Model | RCYQ-10 |

| Diesel Engine | Power | 132kw |

| Manufacturer | Carter Perkins | |

| The Main Machine | Power | 366kw |

| Ways of Controlling | Wired/Wireless (optional) | |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat